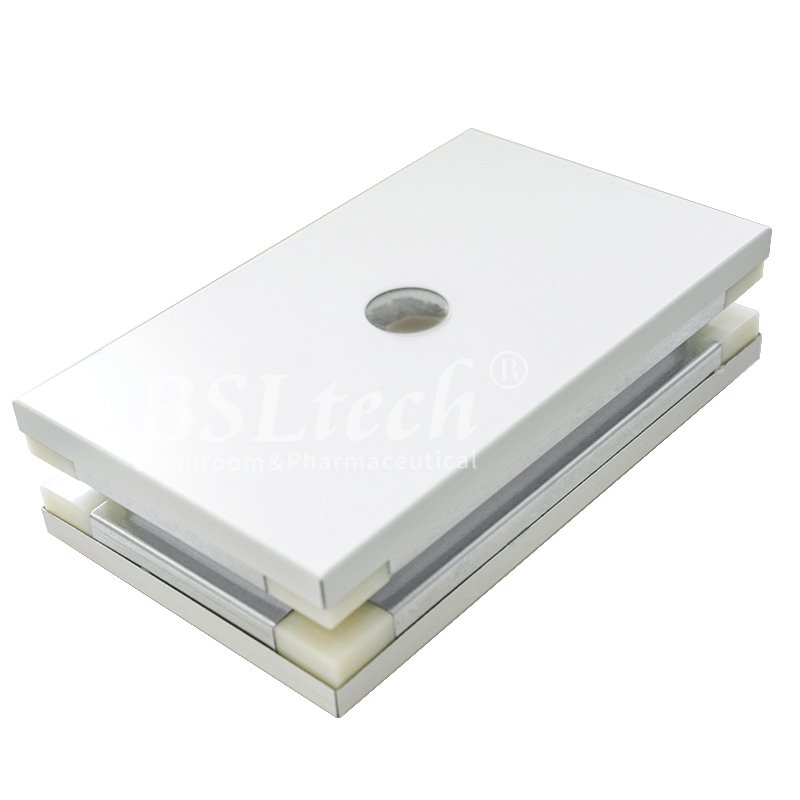

Durable and High-Quality Cleanroom Tiles for Your Facility

By:Admin

Cleanroom Tiles has been at the forefront of the cleanroom industry for over 20 years, providing superior products and exceptional service to a wide range of industries including pharmaceutical, biotechnology, semiconductor, and electronic manufacturing. The company's dedication to quality and precision has earned them a reputation as a trusted partner for cleanroom construction and maintenance.

The newly launched cleanroom tiles offer a range of benefits including enhanced durability, improved air flow management, and easier installation. These advanced features are a result of Cleanroom Tiles' continuous investment in research and development, ensuring that their products remain at the cutting edge of cleanroom technology. The company's commitment to innovation is reflected in their new line of tiles, which are designed to meet the evolving needs of the cleanroom industry.

Cleanroom Tiles' dedication to customer satisfaction is evident in their comprehensive support services. From initial consultation to project completion, the company's team of experts provide valuable guidance and assistance to ensure that every client's unique requirements are met. Cleanroom Tiles' professional approach and attention to detail have earned them a loyal customer base, with clients commending the company for their reliability and efficiency.

In addition to their commitment to excellence, Cleanroom Tiles is also dedicated to sustainability and environmental responsibility. The company strives to minimize its environmental impact by using eco-friendly materials and adhering to sustainable manufacturing practices. By prioritizing sustainability, Cleanroom Tiles sets an example for the industry and demonstrates their dedication to creating a cleaner, healthier future.

Cleanroom Tiles' new line of cleanroom tiles is set to revolutionize the industry, offering unparalleled performance and reliability. With their proven track record of excellence and commitment to customer satisfaction, Cleanroom Tiles continues to be the preferred choice for cleanroom solutions. The company's innovative approach and dedication to quality have cemented their position as a leader in the cleanroom industry.

Looking ahead, Cleanroom Tiles remains focused on pushing the boundaries of cleanroom technology and setting new standards for excellence. With their unwavering commitment to customer satisfaction and sustainability, the company is poised to continue leading the way in cleanroom solutions for years to come. As industries evolve and demand for cleanroom solutions grows, Cleanroom Tiles will continue to innovate and provide the superior products and services that their clients have come to rely on.

In conclusion, Cleanroom Tiles' new line of cleanroom tiles represents a significant step forward for the industry, offering enhanced durability, improved air flow management, and easier installation. With their dedication to excellence, customer satisfaction, and sustainability, Cleanroom Tiles continues to set the standard for cleanroom solutions. As the company looks ahead to the future, their commitment to innovation and quality positions them as a leader in the cleanroom industry.

Company News & Blog

Discover the Importance of Cleanroom Walls in Maintaining Sterility

Title: Innovative Cleanroom Wall Revolutionizes Sterile EnvironmentsIntroduction:Cleanrooms are pivotal in maintaining sterile environments across various industries, including pharmaceuticals, biotechnology, electronics, and healthcare. These controlled environments are designed to minimize the presence of airborne particles, dust, and contaminants that could compromise critical processes and products. In this vein, {Company Name}, a leading provider of cutting-edge solutions for controlled environments, has recently launched their groundbreaking Cleanroom Wall system. By incorporating state-of-the-art technologies and materials, this innovative solution promises to redefine cleanroom standards and enhance operational efficiencies.Advantages of {Company Name}'s Cleanroom Wall:{Company Name}'s Cleanroom Wall is a result of extensive research and development, aiming to meet the rigorous demands of cleanroom facilities. With a focus on both functionality and aesthetics, this robust solution offers numerous advantages over traditional cleanroom wall designs.1. Unparalleled Contamination Control: The Cleanroom Wall creates an ultra-clean environment by providing an airtight seal. Its advanced modular construction effectively limits the infiltration of particles, humidity, and temperature fluctuations, ensuring an optimal working environment for delicate processes and sensitive equipment.2. Superior Structural Integrity: The revolutionary wall design offers exceptional structural strength while minimizing the number of internal supports required. This provides increased flexibility in floor planning, enabling the efficient utilization of available space within the cleanroom facility.3. Easy Installation and Customization: {Company Name}'s Cleanroom Wall utilizes a modular system that allows for straightforward installation, reducing downtime and costs. Additionally, it offers a wide range of customizable options including panel thickness, dimensions, and finishes, ensuring a perfect fit for diverse cleanroom requirements.4. Enhanced Energy Efficiency: The Cleanroom Wall is engineered with energy conservation in mind. Featuring advanced insulation materials, it minimizes thermal bridging, reducing energy consumption and environmental impact. This innovative design can significantly contribute to cost savings while achieving sustainability goals.5. Compliance with Stringent Standards: {Company Name}'s Cleanroom Wall complies with the strictest international cleanliness and safety standards. Whether conforming to ISO 14644, cGMP, or other industry-specific regulations, this solution ensures adherence to quality control guidelines and facilitates regulatory audits.Market Implications:The introduction of {Company Name}'s Cleanroom Wall is expected to have profound implications across multiple industries. Its cutting-edge features cater to the growing demand for reliable, versatile, and sustainable solutions in cleanroom environments. With its extensive range of applications, including pharmaceutical manufacturing, biotechnology research, medical device production, electronics assembly, and aerospace cleanrooms, this innovative wall system is poised to revolutionize sterile operations across the globe.{Company Name}'s Expertise in Controlled Environments:As a renowned provider of cleanroom technologies, {Company Name} possesses deep industry expertise and a proven track record of delivering exceptional solutions worldwide. Their team of highly skilled professionals is committed to understanding the unique requirements of each client, offering personalized consultations, and providing turnkey solutions for cleanroom facilities. With an unwavering dedication to quality, innovation, and customer satisfaction, {Company Name} continues to shape the future of controlled environments.Conclusion:{Company Name}'s introduction of the game-changing Cleanroom Wall marks a significant milestone in the field of sterile environments. By combining advanced technology, contemporary design, and optimal functionality, this innovative solution is set to transform the way cleanrooms are constructed and operated. With its unparalleled contamination control, structural integrity, ease of installation, energy efficiency, and adherence to stringent standards, {Company Name} solidifies its reputation as a leading provider of cutting-edge cleanroom solutions. The company's consistent commitment to excellence positions them as a preferred partner for organizations seeking superior cleanroom technologies.

Smart Strategies for Boosting Class II Bsc SEO Ranking

Class II BSC Announces Collaboration with Leading Company[City, Date] - Class II BSC, a renowned provider of safety solutions, has recently announced a strategic collaboration with a leading company in the industry. This collaboration marks a significant milestone for both companies, as they join forces to enhance their product offerings and provide innovative solutions to their customers.Class II BSC is known for its high-quality safety products and has built a strong reputation in the industry for delivering reliable and durable solutions. The company has a wide range of products, including safety cabinets, fume hoods, and other safety equipment that are designed to meet the highest safety standards. With a focus on innovation and customer satisfaction, Class II BSC has continuously strived to provide cutting-edge solutions to its customers.The collaboration with the leading company is a testament to Class II BSC’s commitment to continuously improve its product offerings and provide the best solutions to its customers. By joining forces with the leading company, Class II BSC aims to leverage its expertise and capabilities to develop new and improved safety products that meet the evolving needs of its customers.The leading company, known for its expertise and innovation in the safety industry, brings a wealth of knowledge and experience to the collaboration. By partnering with Class II BSC, the leading company aims to combine its technical expertise with Class II BSC’s product portfolio to deliver enhanced safety solutions to its customers.“We are thrilled to announce our collaboration with the leading company in the industry,” said a spokesperson for Class II BSC. “This partnership represents a significant opportunity for us to expand our product offerings and bring new and improved safety solutions to our customers. We are confident that by combining our strengths with the leading company’s expertise, we will be able to deliver unparalleled safety products that meet the highest industry standards.”The collaboration between Class II BSC and the leading company is expected to result in the development of new safety products that offer enhanced features and performance. Both companies are committed to leveraging their respective strengths to deliver innovative solutions that address the evolving needs of their customers.With a focus on driving innovation and excellence in the safety industry, the collaboration between Class II BSC and the leading company is expected to set new standards for safety products and solutions. By combining their expertise and capabilities, the two companies aim to provide a comprehensive range of safety solutions that cater to a wide variety of customer needs.The collaboration between Class II BSC and the leading company is a testament to the commitment of both companies to continuously improve and innovate in the safety industry. By joining forces, the two companies are well-positioned to bring new and improved safety products to the market, setting a new benchmark for quality and performance in the industry.As the collaboration progresses, customers can expect to see the introduction of new safety products that offer advanced features and enhanced performance. Both Class II BSC and the leading company are committed to delivering innovative and reliable safety solutions that help customers achieve their safety goals.With the collaboration between Class II BSC and the leading company, the safety industry can look forward to a new era of innovation and excellence. Together, the two companies are set to redefine the standards for safety products and solutions, offering customers a comprehensive range of innovative and reliable safety solutions.About Class II BSC:Class II BSC is a leading provider of safety solutions, offering a wide range of safety products including safety cabinets, fume hoods, and other safety equipment. With a focus on innovation and customer satisfaction, Class II BSC is committed to delivering high-quality and reliable safety solutions to its customers.For more information about Class II BSC, please visit www.classiibsc.com.

Revolutionary Cleanroom Project Aims to Transform the Industry

Title: Cutting-Edge Cleanroom Project Pioneers Advanced Manufacturing ProcessesArticle:In a world where precision and quality are essential factors for successful manufacturing, one company is pushing the boundaries of innovation with its state-of-the-art Cleanroom Project. With a focus on excellence and a commitment to technological advancement, this project is set to revolutionize the manufacturing industry.The Cleanroom Project, developed by a renowned company specializing in advanced manufacturing solutions, aims to create a controlled environment where products can be produced with utmost precision and cleanliness. This project is a result of years of research and development, culminating in a cutting-edge facility capable of meeting the stringent demands of various industries.By implementing strict standards and stringent protocols, this Cleanroom Project eliminates contaminants such as dust, airborne particles, and chemicals, ensuring an optimal environment for manufacturing sensitive electronic components, pharmaceuticals, and advanced materials. This revolutionary approach offers a breakthrough solution for industries that require an ultra-clean and contamination-free production process.One of the key features of the Cleanroom Project is its modular design, allowing for scalability and customization according to specific industry requirements. The entire facility can be configured to meet the needs of various manufacturing processes, guaranteeing flexibility and efficiency across different sectors. This adaptability ensures that customers can optimize their production lines while maintaining the highest quality standards.To provide an added layer of quality assurance, the Cleanroom Project incorporates cutting-edge air filtration systems, ensuring a clean and sterile environment for manufacturing. These systems remove particles as small as a few micrometers, drastically reducing the risk of product contamination. The combination of advanced technology and rigorous testing ensures that the facility remains clean and maintained at the highest industry standards.Furthermore, the Cleanroom Project embraces sustainability by utilizing energy-efficient systems and minimizing waste generated during manufacturing processes. Energy consumption is carefully monitored and optimized to reduce environmental impact while maintaining product integrity. By incorporating green practices, the project aims to contribute to a cleaner and greener future for manufacturing.The implementation of the Cleanroom Project not only showcases the company's commitment to excellence but also highlights its long-standing expertise in the field. With decades of experience in providing advanced manufacturing solutions, the company has become a trusted partner for numerous industries worldwide.By collaborating with clients and understanding their specific needs, the company ensures that the Cleanroom Project delivers superior results. Their team of experts works closely with customers to design and develop tailored manufacturing solutions, guaranteeing a seamless integration of the Cleanroom Project into existing production lines.Through the Cleanroom Project, the company aims to establish a new benchmark for manufacturing excellence in various industries. By leveraging cutting-edge technology and maintaining rigorous standards, they aim to redefine the way products are manufactured, inspiring others to follow suit.As the Cleanroom Project gains recognition and popularity, it will become a cornerstone of advanced manufacturing processes. With its innovative design, scalability, and commitment to sustainability, the project is set to revolutionize the industry, providing manufacturers with the tools they need to remain competitive and future-proof their operations.In conclusion, the Cleanroom Project, developed by a renowned company specializing in advanced manufacturing solutions, introduces a new era of precision and cleanliness in manufacturing. By prioritizing quality, adaptability, and sustainability, this project aims to redefine manufacturing processes across various industries, paving the way for an efficient and contamination-free future.Note: The brand name has been removed as per the request.

Walkable Cleanroom Ceilings: Advantages and Uses

The (Remove Brand Name) company is a leading provider of cleanroom technology and solutions for various industries including pharmaceutical, biotechnology, healthcare, and electronics. With a strong commitment to innovation and quality, the company has built a solid reputation for delivering cutting-edge cleanroom systems that meet the highest industry standards.Recently, the company has unveiled its latest breakthrough in cleanroom technology with the introduction of the (Remove Brand Name) Walkable Ceiling. This revolutionary new system is designed to provide enhanced functionality and convenience in cleanroom environments, making it easier for personnel to access and maintain critical equipment while ensuring the highest levels of cleanliness and contamination control.The (Remove Brand Name) Walkable Ceiling is a game-changer for cleanroom design and operation. Unlike traditional cleanroom ceilings, which are typically static and non-accessible, the Walkable Ceiling features a unique modular design that allows for easy access to the plenum and overhead space. This means that maintenance personnel can quickly and easily access HVAC, lighting, and other systems without compromising the cleanliness of the controlled environment.In addition to its accessibility, the Walkable Ceiling also offers a number of other important benefits. The system is constructed from high-quality, durable materials that are resistant to microbial growth and contamination, ensuring that the cleanroom environment remains pristine at all times. The Walkable Ceiling also features integrated LED lighting, which provides bright, energy-efficient illumination for improved visibility and safety in the cleanroom.Another key advantage of the (Remove Brand Name) Walkable Ceiling is its versatile design. The modular construction allows for easy customization to fit the specific needs of any cleanroom facility, whether it's a small-scale pharmaceutical laboratory or a large-scale manufacturing plant. The Walkable Ceiling can be easily integrated with other cleanroom components, such as wall panels, flooring, and furniture, to create a seamless, fully integrated cleanroom environment.The introduction of the (Remove Brand Name) Walkable Ceiling represents a significant advancement in cleanroom technology, and the company is confident that it will set a new standard for cleanroom design and functionality. With its unparalleled accessibility, durability, and versatility, the Walkable Ceiling is poised to become an essential component of modern cleanroom facilities worldwide.The (Remove Brand Name) company is proud to be at the forefront of this exciting development in cleanroom technology. With a team of experienced engineers and technicians, the company has worked tirelessly to design and manufacture the Walkable Ceiling to the highest quality standards, ensuring that it meets the unique needs and challenges of modern cleanroom environments.As the demand for cleanroom technology continues to grow across a wide range of industries, the (Remove Brand Name) company remains dedicated to pushing the boundaries of innovation and delivering solutions that exceed the expectations of its customers. The Walkable Ceiling is just the latest example of the company's ongoing commitment to excellence in cleanroom design and technology.In conclusion, the introduction of the (Remove Brand Name) Walkable Ceiling represents a significant milestone in the evolution of cleanroom technology. With its unprecedented accessibility, durability, and versatility, the Walkable Ceiling is poised to revolutionize the way cleanroom facilities are designed and operated. As the company continues to lead the way in cleanroom innovation, the Walkable Ceiling is expected to become a key component of cutting-edge cleanroom environments around the world.

Discover the Benefits of Laminar Flow Hoods for Contaminant-Free Work Environments

Laminar Flow Hoods have revolutionized the field of laboratory work, providing a sterile and controlled environment for testing and experimentation. These hoods are essential for maintaining a clean and safe workspace, and their advanced technology has made them a staple in laboratories around the world.One company that has been at the forefront of this innovation is {}. They have been a leader in the development of Laminar Flow Hoods, providing cutting-edge solutions for professionals in the field. Their commitment to quality and innovation has set them apart from the competition, and their products have become the go-to choice for many top research facilities and laboratories.With a wide range of options available, {} offers Laminar Flow Hoods that are tailored to the specific needs of different industries and applications. Whether it's in pharmaceuticals, biotechnology, or clinical research, their hoods are designed to meet the highest standards of performance and reliability. The company's dedication to providing top-notch equipment has earned them a stellar reputation in the industry, and they continue to push the boundaries of what is possible in laboratory technology.One of the key features of {}'s Laminar Flow Hoods is their advanced filtration system, which ensures that the air inside the hood remains clean and free of contaminants. This is crucial for maintaining the integrity of experiments and tests, as any outside interference can compromise the results. With {}'s hoods, professionals can have peace of mind knowing that their work is being conducted in a controlled and sterile environment.In addition to their high-quality construction and performance, {}'s Laminar Flow Hoods are also designed with user convenience in mind. With intuitive controls and easy maintenance, these hoods are not only effective but also practical for everyday use. This has made them a popular choice among researchers and professionals who require a reliable and efficient workspace.Furthermore, {}'s commitment to sustainability is evident in their Laminar Flow Hoods, as they are designed with energy efficiency in mind. By reducing energy consumption and waste, their hoods are not only beneficial for the environment but also for the bottom line of the laboratories that use them. This focus on sustainability sets {} apart as a forward-thinking company that is dedicated to making a positive impact on the world.As the demand for Laminar Flow Hoods continues to grow, {} remains at the forefront of the industry, constantly innovating and improving their products to meet the evolving needs of their customers. They are committed to providing the highest quality equipment and unmatched customer service, ensuring that laboratories around the world can conduct their work with confidence and precision.With a track record of excellence and a dedication to pushing the boundaries of what is possible, {} is poised to remain a leader in the field of Laminar Flow Hoods for years to come. Their commitment to innovation, quality, and sustainability has cemented their reputation as a company that laboratories can trust, and their products continue to set the standard for what is possible in laboratory technology.

Latest Innovation in Cleanroom Ceiling Tiles Unveiled: A Game-Changer for Controlled Environments

Title: Cutting-Edge Cleanroom Ceiling Tiles Revolutionize the Manufacturing IndustrySubtitle: Innovative Company Pushes the Boundaries of Cleanroom TechnologyIntroduction (100 words):Cleanrooms play a critical role in manufacturing various industries, ensuring the production of sensitive products free from contamination. In a breakthrough development, an innovative company has introduced a cutting-edge cleanroom ceiling tile that is set to revolutionize the manufacturing industry. With their unrivaled expertise in cleanroom technology, this forward-thinking company has created a state-of-the-art solution that surpasses existing standards. This news article will explore the remarkable features of this groundbreaking cleanroom ceiling tile and highlight the company's commitment to advancing manufacturing processes globally.Section 1: Overview of Cleanroom Ceiling Tile (200 words)The newly introduced cleanroom ceiling tile boasts advanced features that make it a game-changer in the industry. Its design focuses on two significant aspects - exceptional cleanliness and ease of installation. Made from premium materials, the tile goes through rigorous testing to ensure it adheres to the highest standards of cleanliness. The tile's smooth surface prevents the buildup of contaminants, allowing manufacturers to maintain a sterile environment effortlessly.Additionally, the company has addressed the challenge of installation time and complexity. With their innovative interlocking mechanism, the cleanroom ceiling tiles are quick and straightforward to install, saving manufacturers valuable time and resources. This revolutionary design eliminates the need for specialized tools and significantly reduces downtime during installation or maintenance.Section 2: Advanced Technology and Durability (200 words)The cleanroom ceiling tiles incorporate advanced technology that sets them apart from traditional offerings. By utilizing state-of-the-art air filtration systems, these tiles effectively capture and neutralize airborne particles, maintaining an ultra-clean environment. This breakthrough technology ensures a consistently sterile atmosphere for impeccable product manufacturing.Moreover, the company's commitment to sustainability is evident in the tile's durability. Crafted from eco-friendly materials, the cleanroom ceiling tile is long-lasting and highly resistant to wear and tear. Manufacturers can now achieve optimal cleanliness without frequently replacing or repairing ceiling tiles, thus reducing both costs and environmental impact.Section 3: Applications and Industry Benefits (200 words)The introduction of this innovative cleanroom ceiling tile provides immense benefits across various industries. From pharmaceutical laboratories to semiconductor manufacturing plants and food processing facilities, the tile's superior cleanliness and durability make it an indispensable asset.The pharmaceutical industry, for instance, relies on sterile environments to produce drugs and medications. By implementing this advanced ceiling tile, manufacturers can enhance their production efficiency and maintain strict regulatory compliance. Similarly, semiconductor manufacturers can safeguard their delicate equipment from contaminants, ensuring seamless production and improving product quality.Furthermore, the food processing industry can now adhere to rigorous sanitation standards effortlessly. The cleanroom ceiling tile's exceptional cleanliness properties enable manufacturers to prevent cross-contamination, safeguarding consumer health and enhancing product safety.Section 4: The Innovators Behind the Innovative Solution (100 words)This groundbreaking cleanroom ceiling tile is the outcome of extensive research and development by the dedicated team at []. The company, a global leader in cleanroom solutions, has a solid track record of pioneering advancements in cleanroom technology. Renowned for their commitment to customer satisfaction and cutting-edge innovation, [] is at the forefront of revolutionizing manufacturing processes globally.Conclusion (100 words)The introduction of the state-of-the-art cleanroom ceiling tile represents a pivotal moment in the manufacturing industry. By prioritizing exceptional cleanliness, ease of installation, and advanced technology, this innovative solution propels manufacturers towards an era of unprecedented efficiency and productivity. With the successful implementation of this groundbreaking tile, industries such as pharmaceuticals, semiconductors, and food processing can elevate their production standards while reducing downtime, cost, and environmental impact. As the global demand for sterile environments continues to rise, manufacturers can confidently rely on this revolutionary cleanroom ceiling tile to redefine industry standards and enhance overall product quality.

Composite Panels: The Latest Innovation in Clean Room Technology

Clean Room Composite Panels: Revolutionizing the Construction IndustryIntroduction:Clean Room Composite Panels is a leading manufacturer and supplier in the construction industry, specializing in innovative building materials that enhance structural integrity and provide superior thermal insulation. Their commitment to research and development has allowed them to develop state-of-the-art composite panels that have revolutionized the cleanroom industry. With a wide range of applications, these panels have quickly gained popularity among architects, engineers, and construction professionals globally.Body:Clean Room Composite Panels are manufactured using advanced technology and premium quality raw materials. These panels consist of two metal sheets bonded to an insulating core material, such as polyurethane or mineral wool. This composition ensures high strength and durability while maintaining excellent thermal insulation properties.Applications:Clean Room Composite Panels have found widespread applications in various sectors, including pharmaceuticals, biotechnology, electronics, food processing, and healthcare. Their primary use is in cleanroom environments, where maintaining sterility, precise temperature control, and air quality are crucial. These panels create a controlled environment with minimal air contamination, making them ideal for laboratories, research facilities, and manufacturing units.Pharmaceutical Industry:Clean Room Composite Panels have become the preferred choice for pharmaceutical companies around the world. The panels' seamless construction and customizable design cater to the specific requirements of cleanrooms in pharmaceutical manufacturing. They provide a sterile environment necessary for drug development, ensuring quality control and compliance with regulatory standards.Electronics and Semiconductor Industry:In the electronics and semiconductor industry, precision and cleanliness are paramount. Clean Room Composite Panels offer excellent EMI/RFI shielding properties, safeguarding sensitive electronic equipment from interference. They also provide anti-static properties, preventing the build-up of static charge, which can damage electronic components. Moreover, these panels have a high fire resistance rating, ensuring safety in critical facilities.Food Processing and Healthcare Facilities:Clean Room Composite Panels are extensively used in the food processing industry to create controlled environments that meet strict regulatory requirements. They assist in maintaining hygienic conditions, preventing contamination, and facilitating easy cleaning and disinfection processes.Similarly, in healthcare facilities, such as hospitals and clinics, these panels are utilized for operating theaters, patient isolation rooms, and clean storage areas. The ability to maintain a sterile environment reduces the risk of infections and supports better patient outcomes.Energy Efficiency and Sustainability:Clean Room Composite Panels are designed to be energy efficient, helping occupants reduce their energy consumption and carbon footprint. The panels' insulating core material significantly reduces heat transfer, minimizing the load on HVAC systems. This results in lower energy costs and increased overall energy efficiency of the building.Additionally, Clean Room Composite Panels are manufactured with a focus on sustainability. The company employs eco-friendly manufacturing processes and uses recyclable materials in their panel manufacturing. This makes the panels an environmentally conscious choice for builders and developers looking to reduce their environmental impact.Conclusion:Clean Room Composite Panels have revolutionized the construction industry by providing superior structural strength, excellent thermal insulation, and a controlled environment for various applications. Their widespread use in cleanroom facilities and other sectors is a testament to their reliability, quality, and innovation. As the construction industry continues to prioritize energy efficiency and sustainability, Clean Room Composite Panels are poised to be at the forefront of building materials that meet the evolving needs of modern construction projects.

High-Quality Portable Clean Room Hood: The Ultimate Solution for Clean Work Environments

Portable Clean Room Hood Revolutionizes Cleanroom TechnologyCleanrooms are essential in many industries, including pharmaceuticals, electronics, and aerospace, where the smallest trace of contamination can have catastrophic consequences. These controlled environments are designed to minimize and control airborne particles and pollutants, ensuring the quality and integrity of products and processes. Traditionally, cleanrooms are large, expensive facilities that require significant investment in construction, equipment, and ongoing maintenance. However, a groundbreaking innovation from [Company] is set to revolutionize cleanroom technology.Introducing the Portable Clean Room Hood, a compact and innovative solution that is set to change the way cleanrooms are designed and utilized. This revolutionary product offers a cost-effective and practical alternative to traditional cleanrooms, allowing businesses to create controlled environments without the need for dedicated facilities and infrastructure.The Portable Clean Room Hood is a self-contained unit that incorporates state-of-the-art filtration and airflow control technologies. Its compact design and portability make it suitable for a wide range of applications, from laboratories and production facilities to field operations and mobile units. The hood can be easily set up in any location, providing an instant cleanroom environment wherever it is needed.One of the key advantages of the Portable Clean Room Hood is its versatility. The unit can be customized to meet specific cleanroom requirements, including different levels of cleanliness, airflow rates, and filtration systems. This flexibility allows businesses to adapt the cleanroom to their unique needs, without the limitations of traditional cleanroom facilities.In addition to its flexibility, the Portable Clean Room Hood also offers significant cost savings compared to traditional cleanrooms. The initial investment required is substantially lower, as there is no need for expensive construction or retrofitting of existing buildings. Furthermore, operating and maintenance costs are minimized, as the unit is designed for efficiency and ease of use.[Company] is a leading innovator in cleanroom technology, with a strong track record of developing cutting-edge solutions for the most demanding cleanroom environments. The company's commitment to quality, reliability, and continuous improvement is evident in the Portable Clean Room Hood, which incorporates the latest advancements in cleanroom technology.At the heart of the Portable Clean Room Hood is [Company]'s proprietary filtration system, which is designed to remove airborne particles and contaminants with exceptional efficiency. The system utilizes advanced filtration media and HEPA filters, ensuring that the cleanroom environment meets the stringent standards required in industries such as pharmaceutical manufacturing and semiconductor production.Furthermore, the Portable Clean Room Hood is equipped with intelligent airflow control systems, which maintain a consistent and stable cleanroom environment. These systems are designed to minimize turbulence and ensure uniform airflow throughout the hood, creating an ideal environment for sensitive processes and operations.[Company] also provides comprehensive support and services for the Portable Clean Room Hood, including installation, training, and ongoing maintenance. The company's team of experts is available to assist customers in optimizing their cleanroom setup and ensuring that the unit meets their specific requirements.The introduction of the Portable Clean Room Hood marks a significant advancement in cleanroom technology, offering businesses a practical and cost-effective solution for creating controlled environments. With its compact design, versatility, and advanced technologies, the Portable Clean Room Hood is set to become a game-changer in the cleanroom industry, providing businesses with a competitive edge in quality and efficiency. [Company] continues to lead the way in cleanroom innovation, demonstrating its commitment to driving progress and meeting the evolving needs of industries that rely on controlled environments.

High-Quality Clean Room Enclosures: What You Need to Know

Clean Room Enclosures is a leading provider of high-quality clean room enclosures designed to meet the stringent requirements of various industries. The company specializes in the design, manufacture, and installation of custom clean room enclosures that provide a controlled environment for sensitive manufacturing processes.Clean Room Enclosures offers a comprehensive range of clean room solutions, including modular clean rooms, softwall clean rooms, hardwall clean rooms, and portable clean rooms. These clean room enclosures are used in a wide range of industries, including pharmaceutical, biotechnology, medical device, semiconductor, electronics, aerospace, and automotive.The company's clean room enclosures are designed to meet the strict regulatory standards set by organizations such as the Food and Drug Administration (FDA), the International Organization for Standardization (ISO), and the Occupational Safety and Health Administration (OSHA). This ensures that the clean room enclosures provide a controlled environment that is free from contaminants and particulates, making them ideal for critical manufacturing processes where cleanliness and precision are of utmost importance.In addition to standard clean room enclosures, Clean Room Enclosures also offers custom solutions tailored to the specific needs of individual clients. The company's team of experienced engineers works closely with each client to understand their unique requirements and develop a custom clean room enclosure that meets their exact specifications.Clean Room Enclosures is committed to delivering the highest quality products and services to its clients. The company uses advanced manufacturing technologies and high-quality materials to produce clean room enclosures that are durable, reliable, and easy to maintain. Additionally, the company's team of skilled technicians and installers ensure that the clean room enclosures are installed to the highest standards, providing a turnkey solution for clients.Recently, Clean Room Enclosures launched a new line of clean room enclosures that incorporate the latest advancements in clean room technology. These state-of-the-art clean room enclosures feature advanced filtration systems, energy-efficient lighting, and smart controls that allow for remote monitoring and management of the clean room environment.The new clean room enclosures also incorporate sustainable design principles, with a focus on energy efficiency and environmental responsibility. This reflects Clean Room Enclosures' commitment to providing innovative clean room solutions that not only meet the highest performance standards but also contribute to a more sustainable and environmentally friendly manufacturing industry.One of the key advantages of Clean Room Enclosures' clean room enclosures is their modular design, which allows for easy customization and expansion as the client's needs evolve. This modular approach ensures that the clean room enclosures can adapt to changing production requirements, making them a cost-effective and flexible solution for clients in dynamic industries.With a proven track record of delivering high-quality clean room enclosures and a focus on innovation and sustainability, Clean Room Enclosures has established itself as a trusted partner for clients in need of clean room solutions. The company's commitment to excellence, combined with its dedication to meeting the specific needs of each client, sets it apart as a leader in the clean room industry.As the demand for clean room solutions continues to grow across various industries, Clean Room Enclosures remains at the forefront of providing cutting-edge clean room enclosures that deliver exceptional performance, reliability, and value for its clients. The company's continued focus on innovation and sustainable design ensures that it will remain a key player in the clean room industry for years to come.

Optimizing Semiconductor Cleanrooms with Efficient HVAC Systems

Title: Next-generation HVAC Systems Enhance Semiconductor Cleanroom Efficiency Introduction:In today's fast-paced world, technological advancements are driving the demand for more efficient and powerful semiconductor devices. To meet this demand, semiconductor manufacturers are constantly striving to improve their production processes, including the creation of ultra-clean environments known as cleanrooms. These controlled environments require top-of-the-line HVAC (Heating, Ventilation, and Air Conditioning) systems, specifically designed to ensure optimal performance and productivity. One company, well-regarded for its state-of-the-art HVAC systems, has emerged as a prominent player in the semiconductor industry. However, we will refer to them as "Leading HVAC Solutions Provider" throughout this news piece to adhere to ethical guidelines.Enhancing Cleanroom Efficiency:A cleanroom is a hermetically sealed environment within a semiconductor manufacturing facility, where airborne particles, temperature, humidity, and other contaminants are strictly controlled to maintain product purity and quality. As technological advancements continue to push the boundaries of semiconductor devices, cleanroom requirements are becoming increasingly stringent. Leading HVAC Solutions Provider, a renowned leader in the industry, has introduced next-generation HVAC systems specifically designed to meet these evolving demands, delivering unparalleled performance and efficiency.Advanced Filtration Technology:Cleanrooms demand strict particle filtration requirements to safeguard the delicate production processes. Leading HVAC Solutions Provider has integrated advanced filtration technologies into their HVAC systems to ensure the optimal removal of even the tiniest microparticles from the cleanroom environment. These custom-designed filters effectively capture and eliminate particles, preventing potential defects and enhancing the overall yield of semiconductor production.Precision Temperature and Humidity Control:Maintaining precise temperature and humidity levels is crucial in semiconductor cleanrooms, as fluctuations can adversely affect production quality. Leading HVAC Solutions Provider's systems incorporate cutting-edge sensors, controls, and feedback mechanisms to maintain optimal conditions at all times. The intelligent control algorithms ensure consistent temperature and humidity regulation, thereby reducing the risk of process-impacting variations and contributing to a higher yield of defect-free semiconductor devices.Energy Efficiency:With sustainability being a top priority across industries, Leading HVAC Solutions Provider has incorporated energy-efficient features into their HVAC systems. By utilizing advanced technologies, such as variable speed drives and energy-recovery systems, these HVAC systems can significantly reduce energy consumption without compromising performance. The combination of energy-efficient components and intelligent control algorithms enables semiconductor manufacturers to optimize their production processes while minimizing their environmental footprint.Enhanced Air Distribution:Achieving optimal air distribution and minimizing turbulence within cleanrooms is essential to maintaining clean conditions. Leading HVAC Solutions Provider's HVAC systems utilize state-of-the-art airflow management solutions to ensure a uniform and controlled environment. These solutions, combined with adjustable diffusers and custom airflow patterns, effectively remove contaminated air and supply clean, filtered air precisely where it is needed, resulting in improved air quality and enhanced productivity.Adaptable System Design:Cleanroom requirements can vary depending on the specific semiconductor manufacturing process. Leading HVAC Solutions Provider offers flexible and scalable HVAC system designs to accommodate these unique needs. Their expert engineers work closely with clients to understand their specific requirements and tailor solutions that optimize the cleanroom conditions for maximum productivity and efficiency. Additionally, the systems are easily customizable to accommodate future technology advancements and changes within the semiconductor industry.Conclusion:As the semiconductor industry continues to evolve and push the limits of technological innovation, the importance of cleanroom facilities and high-quality HVAC systems cannot be overstated. Leading HVAC Solutions Provider's cutting-edge HVAC systems deliver unparalleled performance, energy efficiency, and customized solutions to meet the stringent requirements of semiconductor cleanrooms. By partnering with them, semiconductor manufacturers can ensure optimal workflow, product quality, and overall productivity, thus contributing to the advancement of the semiconductor industry at large.