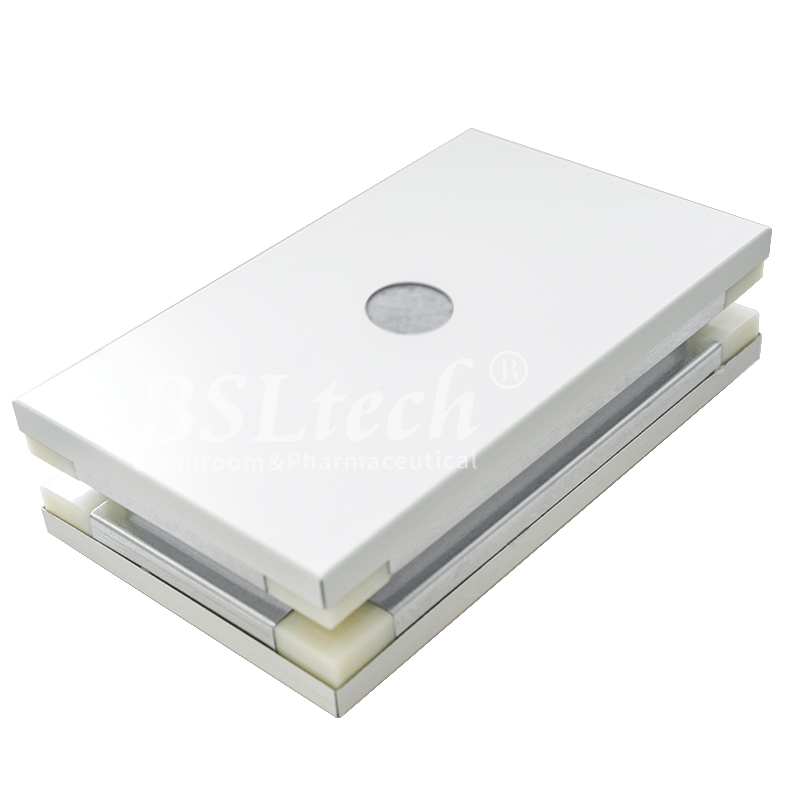

High-quality Portable Cleanroom for Clean and Controlled Environments

By:Admin

Cleanrooms play a crucial role in industries such as pharmaceuticals, biotechnology, electronics, and aerospace, where maintaining a sterile and controlled environment is essential for the production of high-quality products. However, traditional cleanrooms can be expensive, time-consuming to build, and often lack the flexibility to adapt to changing production needs. This is where the innovative Portable Cleanroom by {Company} is making a significant impact.

{Company} is a leading provider of cutting-edge cleanroom technology, renowned for its dedication to quality, innovation, and customer satisfaction. With over 20 years of experience in the industry, {Company} has earned a reputation for delivering top-notch cleanroom solutions to a diverse range of clients.

The Portable Cleanroom developed by {Company} is a game-changer in the world of cleanroom technology. This innovative product offers a cost-effective, versatile, and efficient alternative to traditional cleanrooms. Its modular design allows for easy installation and customization, making it an ideal choice for businesses that require a flexible and adaptable cleanroom solution.

The Portable Cleanroom is designed to meet the highest standards of cleanliness and sterility, ensuring that the products manufactured within it meet the strict regulatory requirements of various industries. Its state-of-the-art filtration system and controlled air quality create the perfect environment for sensitive manufacturing processes, such as pharmaceutical compounding, semiconductor fabrication, and medical device assembly.

One of the key benefits of {Company}'s Portable Cleanroom is its mobility. Unlike conventional cleanrooms, which are permanent structures, the Portable Cleanroom can be easily relocated and reconfigured to meet changing production needs. This level of flexibility allows businesses to save time and money by avoiding the costly and time-consuming construction of a new cleanroom whenever their production requirements change.

Moreover, the Portable Cleanroom's quick installation process minimizes downtime, enabling businesses to start production activities sooner and improve overall operational efficiency. This is particularly beneficial for businesses that operate in rapidly evolving industries with constantly changing product demands.

In addition to its mobility and versatility, the Portable Cleanroom is also designed with sustainability in mind. With energy-efficient HVAC systems and recyclable materials, {Company} is committed to reducing the environmental impact of its cleanroom solutions. This eco-friendly approach resonates with businesses that prioritize sustainability and aligns with global efforts to promote green manufacturing practices.

{Company} has successfully implemented its Portable Cleanroom in a variety of industries, including pharmaceutical manufacturing, biotechnology research, and microelectronics production. Its clients have praised the Portable Cleanroom for its exceptional performance, reliability, and ease of use, making it a preferred choice for businesses seeking a modern and efficient cleanroom solution.

In conclusion, {Company}'s Portable Cleanroom is revolutionizing cleanroom technology by offering a cost-effective, versatile, and sustainable solution for businesses in various industries. Its innovative design, mobility, and environmental friendliness set it apart from traditional cleanrooms, making it an invaluable asset for businesses that require a sterile and controlled manufacturing environment.

With its commitment to excellence and continuous innovation, {Company} is poised to continue leading the way in cleanroom technology, providing businesses with state-of-the-art solutions to meet their evolving production needs. As the demand for cleanroom technology grows across industries, {Company}'s Portable Cleanroom stands out as a reliable and forward-thinking solution for businesses seeking to elevate their manufacturing processes.

Company News & Blog

High-Quality Clean Room Doors: A Guide to Choosing the Best Option

Clean Room Doors provides cutting-edge technology and high-quality solutions for clean room environments. The company specializes in the design, manufacture, and installation of clean room doors, offering a wide range of options to meet the specific needs of various industries, including pharmaceutical, biotechnology, healthcare, and electronics.Clean Room Doors has established itself as a leading provider of clean room solutions, with a strong commitment to innovation, quality, and customer satisfaction. The company's team of highly skilled engineers and technicians work closely with clients to understand their unique requirements and deliver customized door solutions that are tailored to their specific needs.One of the key factors that sets Clean Room Doors apart from its competitors is its focus on advanced technology and continuous improvement. The company invests heavily in research and development to stay at the forefront of the industry, constantly seeking new ways to improve the performance, efficiency, and reliability of its products.Clean Room Doors offers a wide range of door solutions to meet the stringent requirements of clean room environments, including hinged doors, sliding doors, swing doors, and automatic doors. Each door is designed to provide a tight seal, preventing the ingress of contaminants and ensuring the integrity of the clean room environment.In addition to its standard product offerings, Clean Room Doors also provides custom solutions for clients with specific requirements. The company's design and engineering team works closely with clients to develop tailor-made door solutions that meet their exact specifications, ensuring a perfect fit and superior performance.Clean Room Doors takes pride in its commitment to quality and reliability. All of the company's products are manufactured to the highest standards, using top-quality materials and advanced manufacturing processes. Each door undergoes rigorous testing and quality assurance procedures to ensure that it meets the strictest industry standards for clean room environments.The company's dedication to customer satisfaction is reflected in its exceptional customer service. Clean Room Doors provides comprehensive support to clients throughout the entire process, from initial consultation and design to installation and after-sales service. The company's team of experts is always available to provide guidance and assistance, ensuring that clients have a seamless and stress-free experience.Clean Room Doors has earned a solid reputation for its excellence in the industry, with a track record of successful projects and satisfied clients. The company has built strong relationships with a wide network of customers, including leading companies in the pharmaceutical, biotechnology, healthcare, and electronics sectors.With its unwavering dedication to innovation, quality, and customer satisfaction, Clean Room Doors continues to set the standard for clean room solutions. The company's cutting-edge technology, customized approach, and commitment to excellence make it the top choice for clients seeking high-performance door solutions for clean room environments.In conclusion, Clean Room Doors is a leading provider of clean room door solutions, offering a wide range of advanced technology and high-quality products to meet the specific needs of various industries. With its dedication to innovation, quality, and customer satisfaction, the company continues to set the standard for excellence in the industry.

Ultimate Guide to Maintaining a Clean Room

Panel Clean Room, a leading provider of cleanroom solutions for the manufacturing and research industries, has recently announced the launch of a new state-of-the-art cleanroom facility. The company, which has been a pioneer in the cleanroom industry for over a decade, is known for its innovative and customizable cleanroom solutions that meet the specific needs of its clients.With the increasing demand for cleanroom facilities in industries such as pharmaceuticals, biotechnology, and electronics manufacturing, Panel Clean Room has recognized the need to expand its capabilities to meet the growing requirements of its customers. The new cleanroom facility is designed to provide a controlled environment for the manufacturing and testing of sensitive products, ensuring the highest level of quality and safety.The facility features advanced HVAC systems, HEPA filtration, and cleanroom technology to ensure the strictest control of airborne particles and environmental conditions. This allows the company to provide cleanroom solutions that comply with industry standards and regulations, giving their clients peace of mind that their products are being manufactured in the safest and cleanest environment possible.Panel Clean Room's commitment to quality and innovation is evident in their new cleanroom facility, which is designed to meet the specific requirements of each client. The company's team of experts work closely with their clients to understand their unique needs and provide customized cleanroom solutions that meet and exceed their expectations.In addition to its new facility, Panel Clean Room continues to invest in research and development to stay at the forefront of cleanroom technology. The company is dedicated to finding new ways to improve cleanroom design and efficiency, ensuring that their clients have access to the latest advancements in cleanroom technology.With a focus on sustainability, Panel Clean Room also emphasizes the importance of energy efficiency and environmental responsibility in their cleanroom solutions. The company's cleanroom facilities are designed to minimize energy consumption and waste generation, while maintaining the highest standards of cleanliness and safety.Panel Clean Room's dedication to excellence and customer satisfaction has made them a trusted provider of cleanroom solutions for a wide range of industries. The company's commitment to innovation and quality sets them apart in the cleanroom industry, and their new facility further solidifies their position as a leader in the field.As Panel Clean Room continues to expand its capabilities and invest in cutting-edge technology, the company is poised to meet the evolving needs of its clients and maintain its reputation as a top provider of cleanroom solutions. With a focus on customer-driven innovation and a dedication to quality, Panel Clean Room is well-positioned to continue its success in the cleanroom industry for years to come.

Highly Efficient Laminar Flow Clean Room for Contamination Control

Laminar Flow Clean Room: Creating a Sterile Environment for Precision ManufacturingIn the world of precision manufacturing, cleanliness is of paramount importance. One of the key tools in maintaining a sterile environment is the Laminar Flow Clean Room, offered by [Company Name]. This cutting-edge technology provides a controlled environment for the production of sensitive components, ensuring that they meet the highest standards of cleanliness and quality.[Company Name] is a leading provider of cleanroom solutions, specializing in the design and implementation of Laminar Flow Clean Rooms for a wide range of industries, including pharmaceuticals, electronics, and aerospace. With a focus on innovation and precision, [Company Name] has established itself as a trusted partner for companies seeking to enhance the quality and reliability of their manufacturing processes.The Laminar Flow Clean Room is a key component of [Company Name]'s cleanroom solutions. This technology utilizes a high-efficiency particulate air (HEPA) filter to create a laminar airflow, which ensures that airborne particles are effectively removed from the environment. This results in a workspace that is virtually free from contaminants, making it ideal for the production of sensitive components that require a sterile environment.One of the key advantages of the Laminar Flow Clean Room is its ability to protect against the ingress of particulate contamination, which can compromise the quality of manufactured products. By maintaining a consistently low level of airborne particles, this technology helps to minimize the risk of product defects and ensures that components meet the strictest cleanliness standards.In addition to its exceptional cleanliness, the Laminar Flow Clean Room also offers a high degree of control over temperature and humidity, further enhancing its suitability for the production of precision components. This level of environmental control is essential for the consistent and reliable manufacturing of sensitive products, making the Laminar Flow Clean Room an indispensable tool for companies that prioritize quality and reliability.[Company Name]'s expertise in cleanroom solutions extends beyond the technology itself. The company's team of experienced engineers and technicians work closely with clients to design and implement custom cleanroom solutions that meet their specific needs. Whether it's a small-scale cleanroom for research and development or a large-scale production facility, [Company Name] has the expertise to deliver tailored solutions that maximize efficiency and productivity.As a testament to its commitment to excellence, [Company Name] is dedicated to staying at the forefront of cleanroom technology. The company continuously invests in research and development to innovate its cleanroom solutions, ensuring that clients have access to the latest advancements in cleanliness and environmental control.The impact of the Laminar Flow Clean Room extends beyond the realm of manufacturing. In industries such as pharmaceuticals, where product purity is critical to human health and safety, this technology plays a vital role in ensuring that medications and medical devices meet stringent regulatory requirements. By providing a sterile environment for the production of these products, the Laminar Flow Clean Room contributes to the overall quality and reliability of the healthcare products that reach consumers.In the fast-paced and competitive landscape of precision manufacturing, the Laminar Flow Clean Room has emerged as a game-changing technology. Its ability to create a controlled and sterile environment for the production of sensitive components has made it a critical tool for companies that prioritize quality, reliability, and precision. With [Company Name]'s expertise in cleanroom solutions, manufacturers can leverage the power of the Laminar Flow Clean Room to elevate the cleanliness and quality of their products, securing a competitive edge in the market.

Essential Guide to Sterile Hoods for Clean Environments

Medical Company XYZ Introduces Cutting-Edge Sterile Hood to Enhance Safety in Healthcare SettingsMedical Company XYZ has recently introduced a state-of-the-art Sterile Hood aimed at improving safety and sterility in healthcare settings. The Sterile Hood is designed to provide a controlled environment for compounding sterile preparations, ultimately reducing the risk of contamination and ensuring the safety of healthcare professionals and patients.The Sterile Hood, manufactured and developed by Company XYZ, features advanced technology and innovative design to meet the high demands of sterile compounding in healthcare facilities. It is equipped with a high-efficiency particulate air (HEPA) filter system, which effectively removes airborne particles and microorganisms to create a clean and sterile environment for compounding medications.With a commitment to enhancing safety and quality in healthcare, Company XYZ has dedicated extensive resources to research and development, resulting in the creation of the Sterile Hood. The company's expertise in pharmaceutical compounding and sterile preparations has allowed it to identify the need for an advanced solution to mitigate the risk of contamination in healthcare settings."Ensuring the safety and sterility of compounded medications is paramount in healthcare settings. Our Sterile Hood is designed to provide a reliable and controlled environment for sterile compounding, ultimately reducing the risk of contamination and safeguarding the well-being of both healthcare professionals and patients," said a spokesperson from Company XYZ.The Sterile Hood complies with stringent regulatory standards and guidelines for sterile compounding, including those set forth by the United States Pharmacopeia (USP) and the Food and Drug Administration (FDA). Its cutting-edge design and features enable healthcare facilities to uphold the highest standards of sterility and safety in pharmaceutical compounding.In addition to its advanced filtration system, the Sterile Hood is equipped with features such as a touch panel control interface, adjustable airflow velocity, and a spacious working area to accommodate various compounding activities. These features are designed to enhance user comfort and efficiency while ensuring the maintenance of a sterile compounding environment.Company XYZ's Sterile Hood is a versatile solution suitable for a wide range of healthcare settings, including hospitals, compounding pharmacies, and healthcare facilities with in-house pharmaceutical compounding capabilities. By implementing the Sterile Hood, healthcare professionals can effectively mitigate the risk of contamination and ensure the quality and safety of compounded medications.Furthermore, Company XYZ provides comprehensive support and training for healthcare professionals in the proper use and maintenance of the Sterile Hood. This includes guidance on operational procedures, maintenance protocols, and ongoing technical support to maximize the performance and longevity of the equipment.The introduction of the Sterile Hood by Company XYZ underscores its commitment to advancing safety and quality in healthcare. With its innovative design and cutting-edge technology, the Sterile Hood is poised to become a leading solution in sterile compounding, empowering healthcare facilities to uphold the highest standards of sterility and safety in pharmaceutical compounding.As the demand for safe and reliable solutions in healthcare continues to grow, Company XYZ remains at the forefront of innovation, dedicated to providing advanced technologies and products that contribute to the improvement of healthcare practices and patient outcomes.In conclusion, the introduction of Company XYZ's Sterile Hood marks a significant advancement in the field of sterile compounding, offering healthcare facilities a reliable and efficient solution to enhance safety and sterility in pharmaceutical compounding. With its cutting-edge design and advanced features, the Sterile Hood is poised to make a substantial impact on the healthcare industry, ultimately contributing to improved quality and safety in healthcare settings.

Understanding the Importance of Biological Safety Cabinet Class 2

Biological Safety Cabinet Class 2 is made with the highest quality materials and cutting-edge technology, ensuring the safety of laboratory workers and the integrity of valuable research materials. These cabinets are designed to provide maximum protection for personnel, the environment, and the research materials, while also offering ease of use and maintenance.With a mission to provide innovative and reliable solutions for laboratory safety, {Company Name} has been a leader in the design and manufacturing of Biological Safety Cabinets for over 20 years. The company's commitment to excellence and customer satisfaction has made them a trusted partner for laboratories across various industries, including pharmaceuticals, biotechnology, healthcare, and research.The Biological Safety Cabinet Class 2 offered by {Company Name} is equipped with state-of-the-art technology to ensure the highest level of safety and performance. These cabinets are designed to provide a sterile working environment, preventing contamination and ensuring the safety of laboratory personnel. The cabinets also feature a high-efficiency particulate air (HEPA) filter, which provides protection against biohazards and airborne contaminants.One of the key features of the Biological Safety Cabinet Class 2 is its ergonomic design, which allows for easy and efficient use. The cabinets are equipped with a user-friendly control panel, allowing for precise control of airflow, lighting, and other essential functions. This ensures a comfortable and safe working environment for laboratory personnel, while also promoting productivity and efficiency.In addition to providing superior safety and performance, the Biological Safety Cabinet Class 2 is also designed for easy maintenance. The cabinets are constructed with durable and easy-to-clean materials, allowing for quick and thorough cleaning to maintain sterility and safety standards. This not only ensures the integrity of research materials but also prolongs the life of the cabinet, providing long-term value and cost-effectiveness.{Company Name} takes pride in offering comprehensive support and service for their Biological Safety Cabinet Class 2. Their team of experts provides installation, training, and ongoing maintenance to ensure the optimal performance and safety of the cabinets. They also offer customization options to meet the specific needs of their customers, ensuring that each cabinet is tailored to the unique requirements of the laboratory.The Biological Safety Cabinet Class 2 offered by {Company Name} is designed to meet and exceed international safety standards, providing laboratories with peace of mind and confidence in the safety of their research materials and personnel. With their commitment to innovation, reliability, and customer satisfaction, {Company Name} continues to be a leading provider of Biological Safety Cabinets for laboratories worldwide.In conclusion, the Biological Safety Cabinet Class 2 offered by {Company Name} is a testament to their dedication to providing top-quality safety solutions for laboratories. With their advanced technology, ergonomic design, and commitment to customer satisfaction, {Company Name} continues to be a trusted partner for laboratories across various industries. Their Biological Safety Cabinet Class 2 is not only a symbol of safety and reliability but also a testament to their ongoing commitment to excellence in laboratory safety.

High-Quality Cleanroom Partitions: A Key Component for Cleanroom Environments

Cleanroom Partition, a leading supplier of cleanroom solutions, has recently announced the release of their latest cleanroom partition system. This innovative partition system has been specifically designed to meet the growing demand for cleanroom solutions in a variety of industries, including pharmaceuticals, electronics, and biotechnology.Cleanroom Partition has been a frontrunner in the cleanroom industry for over 20 years, offering a wide range of high-quality cleanroom products and services. Their expertise in cleanroom design and construction has earned them a reputation as a trusted and reliable provider of cleanroom solutions.The new cleanroom partition system is the result of extensive research and development, aimed at addressing the evolving needs of cleanroom facilities. The partition system features a modular design, allowing for easy installation and customization to fit the specific requirements of each cleanroom environment. It is also highly adaptable, making it suitable for both new cleanroom construction projects and retrofitting existing cleanroom facilities.One of the key advantages of the new cleanroom partition system is its flexibility. It can be easily reconfigured to accommodate changes in workflow or equipment layout, providing cleanroom operators with the ability to optimize their facility for improved efficiency and productivity. This adaptability ensures that the cleanroom partition system can grow and evolve alongside the needs of the facility, making it a valuable long-term investment for cleanroom operators.In addition to its flexibility, the cleanroom partition system also offers exceptional cleanliness and contamination control. It is constructed from high-quality materials that are resistant to microbial growth and easy to clean, ensuring that the cleanroom environment remains sterile and free from potential sources of contamination. This is particularly important for industries such as pharmaceuticals and biotechnology, where maintaining a clean and sterile environment is critical to the success of their operations.Cleanroom Partition has also placed a strong emphasis on the environmental sustainability of their new partition system. The materials used in its construction are eco-friendly and recyclable, contributing to a more sustainable cleanroom solution that aligns with the growing focus on environmentally responsible practices in the industry.As with all of Cleanroom Partition's products, the new cleanroom partition system is backed by their commitment to exceptional customer service and support. Their team of cleanroom experts is available to provide guidance and assistance throughout the installation process, ensuring that the cleanroom partition system is seamlessly integrated into the facility and meets the specific needs of the client.The release of this new cleanroom partition system further solidifies Cleanroom Partition's position as a leader in the cleanroom industry. With its focus on flexibility, cleanliness, and sustainability, the partition system is poised to set a new standard for cleanroom solutions and provide cleanroom operators with a reliable and efficient means of maintaining a sterile and controlled environment.Cleanroom Partition continues to innovate and evolve its product offerings, staying at the forefront of advancements in cleanroom technology and design. Their dedication to providing high-quality cleanroom solutions, combined with their extensive industry experience, makes them a trusted partner for organizations seeking to establish or enhance their cleanroom facilities.As the demand for cleanroom solutions continues to grow across a wide range of industries, Cleanroom Partition remains committed to delivering superior products and services that meet the evolving needs of cleanroom operators. The release of their new cleanroom partition system is a testament to this commitment, and reinforces their standing as a leading supplier of cleanroom solutions in the industry.

High-Quality Wall Material for Cleanrooms

Cleanroom Wall Material Enhances Contamination Control for The CompanyAs a leading provider of cleanroom solutions for various industries, The Company is constantly seeking new technologies and materials to enhance contamination control and improve the overall performance of cleanroom environments. Recently, the company has incorporated a new cleanroom wall material into their cleanroom designs, which has demonstrated exceptional performance in reducing contamination and meeting strict industry standards.The new cleanroom wall material, manufactured by a renowned industry supplier, is made of high-quality materials that are specifically designed to meet the stringent requirements of cleanroom environments. It offers excellent protection against dust, particles, and other contaminants, making it an ideal choice for The Company's cleanroom projects.With the installation of this advanced cleanroom wall material, The Company aims to provide its clients with enhanced contamination control and improved cleanliness in their cleanroom environments. This new material will enable the company to offer even more reliable and efficient cleanroom solutions to industries such as pharmaceuticals, biotechnology, electronics, and semiconductor manufacturing.The Company's decision to adopt this new cleanroom wall material is in line with its commitment to providing cutting-edge technologies and innovative solutions to its clients. By leveraging the latest advancements in cleanroom materials, the company is able to stay at the forefront of the industry and meet the evolving needs of its customers.Incorporating the new cleanroom wall material into its cleanroom designs is just one example of The Company's dedication to maintaining the highest standards of cleanliness and contamination control. The company has long been recognized for its expertise in creating custom cleanroom solutions that meet the specific requirements of each client, and the addition of this advanced wall material further underscores its commitment to excellence.The new cleanroom wall material has undergone rigorous testing and certification to ensure its compliance with industry standards and regulations. Its exceptional performance in reducing contamination and maintaining cleanliness makes it a valuable addition to The Company's portfolio of cleanroom solutions.The Company's cleanroom solutions are known for their reliability, efficiency, and ability to meet the most stringent cleanliness requirements. The incorporation of the new cleanroom wall material further enhances the company's ability to deliver state-of-the-art cleanroom environments that exceed clients' expectations and set new benchmarks for contamination control.With the integration of the advanced cleanroom wall material, The Company is poised to offer even more effective contamination control and enhanced cleanliness to its clients. This will enable the company to continue serving a wide range of industries with superior cleanroom solutions that help uphold the highest standards of product quality and safety.In conclusion, the adoption of the new cleanroom wall material represents a significant advancement for The Company and its commitment to delivering exceptional cleanroom solutions. By incorporating this advanced material into its cleanroom designs, the company is better equipped to provide unmatched contamination control and cleanliness for its clients across various industries. This latest development further solidifies The Company's position as a leading provider of cutting-edge cleanroom solutions that consistently exceed industry standards and customer expectations.

A Comprehensive Guide to Cleanroom Color Steel Sandwich Panels

Cleanroom Color Steel Sandwich Panel: Revolutionizing the Construction IndustryIn today's fast-paced world, technology is constantly evolving, and industries are continuously seeking innovative solutions to streamline their operations. The construction industry is no exception. With the rising demand for high-quality, efficient, and safe construction materials, companies are on the lookout for cutting-edge solutions that can meet these requirements. One such breakthrough is the Cleanroom Color Steel Sandwich Panel, a revolutionary product that is transforming the way we construct cleanrooms and controlled environments.Before delving into the specifics of this groundbreaking product, let's take a closer look at the company behind its development and production. As a leader in the construction materials industry, {company name} has a proven track record of delivering top-notch products and services. With their expertise and commitment to innovation, they have successfully manufactured and introduced the Cleanroom Color Steel Sandwich Panel to address the unique challenges faced by the cleanroom construction industry.Cleanrooms are highly specialized environments used in various industries, including pharmaceuticals, electronics, healthcare, and research laboratories, where even the smallest contaminants can have severe implications. Designing and constructing these sensitive areas require meticulous attention to detail and the use of state-of-the-art materials that meet stringent international standards. This is where the Cleanroom Color Steel Sandwich Panel truly shines.The Cleanroom Color Steel Sandwich Panel is manufactured with precision using advanced technology and high-quality materials. This product comprises two external layers of galvanized color steel sheets, sandwiching an inner core of polyurethane foam. This unique sandwich structure provides exceptional insulation, durability, and strength, making it an ideal choice for cleanroom construction.One of the key advantages of the Cleanroom Color Steel Sandwich Panel is its ability to create an airtight seal, preventing the infiltration of pollutants and maintaining the desired cleanliness levels within the controlled environment. The tight joints between panels, engineered by {company name}, eliminate any gaps that may compromise the integrity of the cleanroom. As a result, the risk of cross-contamination is significantly minimized, ensuring optimal safety and compliance with industry regulations.Additionally, the Cleanroom Color Steel Sandwich Panel offers excellent thermal insulation. The polyurethane foam core acts as a highly efficient insulation material, reducing energy consumption and providing a stable and comfortable environment for cleanroom occupants. Its insulation properties also contribute to noise reduction, enhancing the work environment further.In terms of aesthetics, the Cleanroom Color Steel Sandwich Panel is available in a range of colors and finishes, allowing architects and designers the flexibility to create visually appealing cleanroom spaces. The panels can be customized to meet specific project requirements, ensuring a seamless integration into any cleanroom design.Moreover, the Cleanroom Color Steel Sandwich Panel exhibits superb fire-resistant properties, making it a reliable choice for environments where fire safety is of paramount importance. This inherent fire resistance is achieved through cutting-edge testing methods, confirming its ability to withstand extreme conditions and providing peace of mind to cleanroom operators.The introduction of the Cleanroom Color Steel Sandwich Panel has undoubtedly revolutionized the construction industry, particularly in cleanroom applications. With its exceptional insulation properties, airtight seal, and fire resistance, this innovative product offers a game-changing solution for cleanroom construction. By partnering with {company name}, industries can benefit from their expertise and gain access to this remarkable product, ensuring the creation of safe, efficient, and aesthetically pleasing cleanroom environments.

High-Quality Clean Room Ceiling Options for Your Facility

Clean Room Ceiling, a leading company in the field of clean room ceiling systems, has recently made significant advancements in their technology that ensures a highly controlled environment for a variety of industries. With their state-of-the-art clean room ceilings, the company is dedicated to providing a safe and sterile environment for pharmaceutical, biotechnology, healthcare, and electronics manufacturing facilities.Clean Room Ceiling's cutting-edge technology focuses on ensuring the purity and cleanliness of the air within the controlled environment. This is achieved through their innovative ceiling systems that are designed to effectively filter out airborne particles and contaminants, ensuring a sterile environment for sensitive processes and manufacturing.The company's clean room ceiling systems are meticulously engineered to meet the stringent requirements of various industries, including pharmaceutical and biotechnology, where the production of medicines and other medical products requires an environment free from any form of contamination. Clean Room Ceiling's advanced technology ensures that these critical environments remain free from pollutants and other harmful particles, thus ensuring the safety and efficacy of the products being manufactured.In addition to the pharmaceutical and biotechnology industries, Clean Room Ceiling also caters to the needs of the healthcare sector. Their clean room ceiling systems are designed to provide a clean and sterile environment for medical facilities, ensuring the safety and well-being of patients and medical staff. With an unwavering commitment to quality and innovation, Clean Room Ceiling has become a trusted partner for healthcare facilities seeking to maintain the highest standards of cleanliness and sterility.Furthermore, Clean Room Ceiling's advanced technology is also crucial for the electronics manufacturing industry, where the production of sensitive electronic components requires an environment free from dust, particulates, and other contaminants. Clean Room Ceiling's clean room ceiling systems ensure that the manufacturing processes remain unaffected by external pollutants, thereby enhancing the quality and reliability of electronic products.The company's dedication to innovation and excellence has positioned them as a leader in the field of clean room ceiling systems. Their commitment to providing cutting-edge solutions for controlled environments has earned them a solid reputation in the industry, with many businesses and organizations relying on their technology to maintain the highest standards of cleanliness and purity.Clean Room Ceiling's team of experts are continuously researching and developing new technologies to further enhance the performance of their clean room ceiling systems. Their relentless pursuit of excellence and their unwavering commitment to providing the best solutions for controlled environments have set them apart as an industry leader.In conclusion, Clean Room Ceiling's advancements in clean room ceiling technology are a testament to their dedication to providing the highest standards of cleanliness and sterility for a variety of industries. With their innovative solutions and commitment to excellence, the company continues to be a trusted partner for businesses and organizations seeking to maintain a clean and controlled environment for their critical processes and operations.

Essential Biosafety Cabinet: Ensuring Safety in Laboratories & Research Facilities

Title: Cutting-edge Biosafety Cabinet Enhances Laboratory Safety and EfficiencyIntroduction:In today's rapidly advancing scientific landscape, maintaining a high level of biosafety is of utmost importance. Biobase, a leading provider of laboratory equipment, is revolutionizing the biosafety industry with its state-of-the-art biosafety cabinet. This cutting-edge technology ensures optimal protection for researchers and their delicate samples, while also enhancing laboratory efficiency and productivity.Ensuring a Safe Laboratory Environment:Biobase's advanced biosafety cabinet offers a comprehensive solution for laboratory safety, minimizing the risk of contamination and protecting researchers from hazardous substances. The cabinet is designed with several key features to guarantee a safe working environment. These include HEPA (High-Efficiency Particulate Air) filters, which capture and remove harmful particles from the air, preventing their escape into the laboratory. The cabinet is also equipped with an advanced air circulation system that maintains a constant negative pressure, effectively containing any potential contaminants within the enclosed area.Enhanced Ergonomics:Recognizing the importance of user comfort and convenience, Biobase has integrated ergonomic features into their biosafety cabinet design. Researchers can adjust the working height, optimizing the cabinet's accessibility and minimizing the risk of strain or injury during prolonged laboratory operations. Furthermore, the cabinet's interior is designed to maximize the available workspace, providing ample room for various laboratory tasks, equipment, and additional precautionary measures.Smart Control System:Biobase's biosafety cabinet incorporates an intelligent control system that simplifies operation and enhances workflow efficiency. This intuitive interface allows researchers to modify settings such as airflow, temperature, and lighting, ensuring optimal conditions for sample handling. The cabinet also includes real-time airflow monitoring, providing immediate notifications in case of any disruptions or potential risks. By automating previously time-consuming manual processes, the intelligent control system significantly improves laboratory productivity.Advanced Filtration Technology:Biobase's dedication to excellence is evident in the development of their advanced filtration technology featured in the biosafety cabinet. The upgraded HEPA filters effectively remove airborne contaminants down to 0.3 microns, providing a highly sterile environment for critical laboratory procedures. Additionally, these filters are easily replaceable, ensuring continuous protection and maintaining long-term performance. Biobase's emphasis on filtration technology ensures researchers can execute their experiments and handle delicate samples with confidence and accuracy.Versatility and Customization:Biobase understands that different laboratory setups require flexibility. Therefore, their biosafety cabinet is designed with various sizes and configurations, accommodating the diverse needs of different research facilities. Whether it involves additional workspace, specialized monitoring systems, or custom integration with other laboratory equipment, Biobase offers comprehensive customization options. Not only does this enhance efficiency within existing laboratory spaces, but it also allows for future scalability as research requirements evolve.Collaboration with Global Research Institutions:Biobase has developed a strong network of collaborations with renowned research institutions worldwide. This collaborative approach allows for continuous improvement and innovation, ensuring that their biosafety cabinets remain at the forefront of laboratory safety. By actively seeking feedback from researchers and incorporating their insights into ongoing product enhancements, Biobase continues to redefine industry standards.Conclusion:Biobase's biosafety cabinet represents a significant leap forward in laboratory safety and efficiency. With its cutting-edge features, robust filtration technology, and customizable options, Biobase is committed to providing the highest level of biosafety protection to researchers. By safeguarding laboratories, this innovative solution ultimately promotes groundbreaking scientific advancements without compromising on safety.