High-quality Biosafety Cabinet for Laboratory Use

By:Admin

In recent news, Nuaire has launched a new generation of biosafety cabinets that offer advanced levels of protection for both personnel and the environment. The new cabinets incorporate the latest technology to ensure optimal performance and efficiency, making them ideal for a wide range of applications in research laboratories, clinical facilities, and production environments.

The Nuaire biosafety cabinets are designed to provide a safe and controlled environment for handling hazardous materials, such as infectious agents, toxins, and other potentially harmful substances. With features such as HEPA filtration, airflow monitoring, and ergonomic design, these cabinets offer superior levels of protection, ensuring the safety of personnel and the integrity of the work being conducted.

One of the key features of the new biosafety cabinets is their robust construction, which is engineered to withstand the rigors of daily use in demanding laboratory settings. The cabinets are also designed to be easy to clean and maintain, reducing the risk of contamination and minimizing downtime for maintenance and servicing.

With a focus on user safety and comfort, Nuaire's biosafety cabinets are equipped with intuitive controls and ergonomic design features that enhance the overall user experience. This includes adjustable work surfaces, customizable airflow patterns, and user-friendly interfaces that make operation and maintenance straightforward and efficient.

In addition to their advanced safety features, the new biosafety cabinets from Nuaire are also designed to be energy-efficient, helping to reduce the environmental impact of laboratory operations. By optimizing airflow patterns and implementing energy-saving technologies, these cabinets contribute to a more sustainable and eco-friendly working environment.

Nuaire's commitment to quality and innovation is reflected in the company's comprehensive support services, which include installation, training, and ongoing technical support. This ensures that customers can maximize the performance and longevity of their biosafety cabinets, while also maintaining compliance with industry regulations and best practices.

As a global leader in biosafety cabinets and clean air solutions, Nuaire is dedicated to supporting the scientific community in achieving its research and development goals. By providing state-of-the-art equipment that meets the highest standards of safety, quality, and performance, Nuaire is helping to advance scientific progress and improve the well-being of society.

With the launch of its new generation of biosafety cabinets, Nuaire continues to demonstrate its commitment to excellence and innovation. By combining advanced technology, robust construction, and user-focused design, these cabinets set a new standard for safety, efficiency, and reliability in laboratory environments.

As the scientific community continues to pursue groundbreaking discoveries and advancements, Nuaire is proud to be a trusted partner, providing the tools and support needed to drive progress and ensure a safe and sustainable future for all.

Company News & Blog

High-Quality Softwall Clean Room for Contamination Control

Softwall Clean Room Market is anticipated to grow at a CAGR of 6% during the forecast period of 2022-2027, according to a recent market research report. The market is expected to witness significant growth due to the increasing demand for contamination-free manufacturing environments in various industries such as pharmaceuticals, biotechnology, and electronics.A softwall clean room is a controlled environment that is designed to maintain extremely low levels of pollutants such as dust, airborne microbes, aerosol particles, and chemical vapors. These clean rooms are typically used in industries where product quality and safety are of utmost importance. They are also utilized in research and development facilities and laboratories where a sterile environment is necessary to perform critical experiments and tests.The market for softwall clean rooms is being driven by the growing emphasis on product quality and safety in industries such as pharmaceuticals and biotechnology. The stringent regulatory requirements for manufacturing and testing processes in these industries have led to an increased adoption of clean room technology. Additionally, the rising demand for precision manufacturing in the electronics industry is also fueling the growth of the softwall clean room market.One of the key players in the softwall clean room market, {Company Name}, is known for its innovative clean room solutions that are designed to meet the unique requirements of different industries. The company offers a wide range of softwall clean room systems that are customizable and can be tailored to specific applications. These clean rooms are equipped with advanced filtration and ventilation systems to maintain the desired level of cleanliness and air quality.{Company Name} has a track record of delivering high-quality clean room solutions that exceed industry standards. The company's team of experts works closely with clients to understand their clean room requirements and provides customized solutions that meet their specific needs. With a focus on innovation and continuous improvement, {Company Name} is committed to delivering cutting-edge clean room technologies that help clients achieve the highest levels of product quality and safety.In addition to its advanced clean room systems, {Company Name} also offers a range of services such as clean room validation, testing, and maintenance to ensure that the clean rooms continue to meet the required standards over time. The company's comprehensive approach to clean room solutions has made it a preferred choice for many leading companies in the pharmaceutical, biotechnology, and electronics industries.As the demand for contamination-free manufacturing environments continues to rise, {Company Name} is well-positioned to capitalize on the opportunities in the growing softwall clean room market. With its expertise in clean room technology and a commitment to customer satisfaction, the company is poised to further expand its presence in the global market.In conclusion, the softwall clean room market is projected to experience significant growth in the coming years, driven by the increasing demand for contamination-free manufacturing environments in various industries. {Company Name} is a leading player in this market, known for its innovative clean room solutions and commitment to customer satisfaction. With its focus on delivering high-quality clean room technologies, the company is well-positioned to capitalize on the opportunities in the growing market and further expand its global presence.

High-quality Cleanroom Enclosures for Various Industries

Cleanroom Enclosures, a leading provider of cleanroom solutions for various industries, has recently introduced a new line of state-of-the-art cleanroom enclosures designed to meet the growing demand for high-quality, customizable cleanroom solutions.The company, known for its innovative approach to cleanroom design and construction, has been serving the pharmaceutical, biotechnology, medical device, semiconductor, and aerospace industries for over 20 years. With a focus on quality, performance, and customer satisfaction, Cleanroom Enclosures has established itself as a trusted partner for companies looking to create controlled environments for their critical processes.The new line of cleanroom enclosures is the result of extensive research and development, as well as feedback from customers and industry experts. These enclosures are designed to provide a modular, flexible, and cost-effective solution for companies looking to create cleanrooms for various applications.One of the key features of the new cleanroom enclosures is their modular design, which allows for easy customization and reconfiguration to meet specific requirements. This flexibility is particularly beneficial for companies with evolving needs, as it enables them to adapt their cleanroom space as their processes and operations change.In addition, the cleanroom enclosures are constructed using high-quality materials and advanced manufacturing techniques to ensure superior performance and reliability. This includes advanced HVAC systems for precise temperature and humidity control, as well as HEPA filtration to maintain cleanliness and air quality within the enclosure.Another important aspect of the new cleanroom enclosures is their compliance with industry standards and regulations. Cleanroom Enclosures has designed these enclosures to meet or exceed the stringent requirements of various regulatory bodies, including ISO, FDA, and cGMP. This ensures that companies can rely on these enclosures to provide a controlled environment that meets the highest standards for safety and quality.Furthermore, Cleanroom Enclosures is committed to providing exceptional customer service and support throughout the entire process, from initial consultation to installation and beyond. The company’s team of experts works closely with customers to understand their specific needs and develop tailored solutions that meet or exceed their expectations.With its proven track record of delivering high-quality cleanroom solutions, Cleanroom Enclosures has built a strong reputation in the industry. The company prides itself on its ability to deliver reliable, cost-effective, and innovative cleanroom solutions that help its customers achieve their goals.The introduction of the new line of cleanroom enclosures further solidifies Cleanroom Enclosures’ position as a leader in the industry. With its commitment to excellence, attention to detail, and focus on customer satisfaction, the company continues to set the standard for cleanroom solutions that meet the evolving needs of modern industries.As the demand for cleanroom solutions continues to grow across various sectors, Cleanroom Enclosures is well-positioned to meet the needs of companies looking for cutting-edge, reliable, and customizable cleanroom enclosures. With its new line of enclosures, the company is poised to continue its legacy of innovation and leadership in the industry.In conclusion, Cleanroom Enclosures’ new line of cleanroom enclosures represents a significant advancement in the industry, offering a modular, flexible, and compliant solution for companies in need of controlled environments. With its commitment to quality, performance, and customer satisfaction, Cleanroom Enclosures is poised to continue its success as a trusted provider of cleanroom solutions for the pharmaceutical, biotechnology, medical device, semiconductor, and aerospace industries.

Guide to Clean Room Hmi Systems and Applications

Clean Room HMI Technology Revolutionizing Clean Room OperationsIn the world of clean room operations, maintaining a sterile environment is of utmost importance. Any slight contamination can have serious consequences, making it essential for companies to invest in the latest technologies to ensure the highest standards of cleanliness and efficiency. This is where Clean Room HMI Technology comes into play, revolutionizing the way clean room operations are managed and monitored.Clean Room HMI is a cutting-edge technology that provides real-time monitoring and control of clean room operations. It offers a user-friendly interface that allows operators to monitor all aspects of the clean room, including temperature, humidity, pressure, and contamination levels. This technology provides a comprehensive overview of the clean room environment, enabling operators to make informed decisions to maintain the integrity of the sterile environment.With the increasing demand for clean room technology, {} has emerged as a leading provider of Clean Room HMI solutions. The company has a proven track record of delivering state-of-the-art technology that meets the stringent requirements of clean room operations. With a team of experienced engineers and scientists, {} is dedicated to providing innovative solutions that streamline clean room operations and ensure the highest levels of cleanliness and safety.One of the key features of {}'s Clean Room HMI technology is its integration with advanced monitoring and control systems. This integration allows for seamless communication between different components of the clean room, ensuring optimal performance and efficiency. With real-time data visualization and analysis, operators can quickly identify any deviations from the set parameters and take immediate corrective actions to maintain the sterile environment.Furthermore, {}'s Clean Room HMI technology is designed to be highly customizable, allowing for seamless integration with existing clean room systems. This flexibility enables companies to upgrade their clean room operations without the need for a complete overhaul of their existing infrastructure. This not only saves time and money but also ensures minimal disruption to the ongoing operations.In addition to its monitoring and control capabilities, {}'s Clean Room HMI technology also offers advanced data management features. Operators can store and analyze historical data to identify trends and patterns, enabling them to make informed decisions to optimize clean room operations. The ability to access and analyze historical data is crucial for identifying potential issues and implementing proactive measures to prevent contamination and ensure compliance with regulatory standards.As the demand for clean room technology continues to grow, {} remains at the forefront of innovation, constantly developing and improving its Clean Room HMI solutions. With a focus on quality, reliability, and customer satisfaction, {} is committed to delivering technology that exceeds the expectations of its clients and contributes to the advancement of clean room operations across diverse industries.In conclusion, Clean Room HMI technology is transforming the way clean room operations are managed, providing real-time monitoring, control, and data management capabilities that ensure the highest standards of cleanliness and efficiency. As a leading provider of Clean Room HMI solutions, {} continues to lead the way in delivering innovative technology that meets the evolving needs of clean room operations. With a dedication to excellence and a commitment to customer satisfaction, {} is poised to play a pivotal role in the future of clean room technology.

Understanding the Importance of Laminar Hood Flow in Laboratory Safety

Title: Company X Introduces State-of-the-Art Laminar Hood Flow TechnologyCompany X, a leader in the field of scientific equipment and laboratory technology, is proud to introduce their latest innovation in Laminar Hood Flow technology. This advancement is set to revolutionize the way laboratories operate and conduct their research, providing a clean and controlled environment for various scientific applications.The Laminar Hood Flow technology offered by Company X ensures a sterile and particle-free workspace, making it an essential tool for any laboratory setting. This cutting-edge technology is designed to minimize contamination and provide a constant flow of clean air, creating an ideal environment for conducting sensitive experiments and handling delicate materials.One of the key features of the Laminar Hood Flow technology produced by Company X is its ability to maintain a constant and uniform airflow within the workspace. This ensures that any airborne contaminants are swiftly removed, guaranteeing the integrity of the research being conducted and the safety of the personnel working in the laboratory.In addition, Company X's Laminar Hood Flow technology is equipped with advanced filtration systems that effectively capture and eliminate any microscopic particles that may compromise the integrity of the work being carried out in the lab. This level of precision and control is crucial for industries such as pharmaceuticals, biotechnology, and medical research, where maintaining a sterile environment is paramount.Company X's commitment to delivering high-quality and innovative solutions is exemplified by their investment in research and development. The introduction of their Laminar Hood Flow technology is a testament to their dedication to meeting the evolving needs of the scientific community and ensuring the highest standards of safety and efficiency in laboratory environments.The versatility of Company X's Laminar Hood Flow technology makes it suitable for a wide range of applications, from microbiology and cell culture to pharmaceutical production and electronic device assembly. Its flexibility and adaptability make it a valuable asset for any laboratory or cleanroom setting, where precision and cleanliness are non-negotiable.Furthermore, Company X offers customizable options for their Laminar Hood Flow technology, allowing clients to tailor the equipment to their specific needs and requirements. This level of personalization ensures that every laboratory can benefit from the cutting-edge technology provided by Company X, regardless of their size or scope of operations.The introduction of Company X's Laminar Hood Flow technology exemplifies their commitment to pushing the boundaries of scientific equipment and laboratory technology. By offering a solution that addresses the pressing need for clean and controlled workspaces, Company X is at the forefront of driving innovation in the scientific community and facilitating groundbreaking research and discoveries.For laboratories and cleanroom facilities looking to elevate their standards of cleanliness and precision, Company X's Laminar Hood Flow technology is the ultimate solution. With its state-of-the-art features, customizable options, and uncompromising commitment to quality, it is set to become an indispensable tool for the advancement of scientific research and experimentation.In conclusion, Company X's Laminar Hood Flow technology represents a significant leap forward in the field of laboratory technology. Its introduction brings with it a new standard of cleanliness and precision, ensuring that laboratories and cleanroom facilities have access to the most advanced tools for their scientific endeavors. As Company X continues to innovate and push the boundaries of scientific equipment, their Laminar Hood Flow technology stands as a testament to their unwavering dedication to excellence.

Essential Guide to Sterile Hoods for Clean Environments

Medical Company XYZ Introduces Cutting-Edge Sterile Hood to Enhance Safety in Healthcare SettingsMedical Company XYZ has recently introduced a state-of-the-art Sterile Hood aimed at improving safety and sterility in healthcare settings. The Sterile Hood is designed to provide a controlled environment for compounding sterile preparations, ultimately reducing the risk of contamination and ensuring the safety of healthcare professionals and patients.The Sterile Hood, manufactured and developed by Company XYZ, features advanced technology and innovative design to meet the high demands of sterile compounding in healthcare facilities. It is equipped with a high-efficiency particulate air (HEPA) filter system, which effectively removes airborne particles and microorganisms to create a clean and sterile environment for compounding medications.With a commitment to enhancing safety and quality in healthcare, Company XYZ has dedicated extensive resources to research and development, resulting in the creation of the Sterile Hood. The company's expertise in pharmaceutical compounding and sterile preparations has allowed it to identify the need for an advanced solution to mitigate the risk of contamination in healthcare settings."Ensuring the safety and sterility of compounded medications is paramount in healthcare settings. Our Sterile Hood is designed to provide a reliable and controlled environment for sterile compounding, ultimately reducing the risk of contamination and safeguarding the well-being of both healthcare professionals and patients," said a spokesperson from Company XYZ.The Sterile Hood complies with stringent regulatory standards and guidelines for sterile compounding, including those set forth by the United States Pharmacopeia (USP) and the Food and Drug Administration (FDA). Its cutting-edge design and features enable healthcare facilities to uphold the highest standards of sterility and safety in pharmaceutical compounding.In addition to its advanced filtration system, the Sterile Hood is equipped with features such as a touch panel control interface, adjustable airflow velocity, and a spacious working area to accommodate various compounding activities. These features are designed to enhance user comfort and efficiency while ensuring the maintenance of a sterile compounding environment.Company XYZ's Sterile Hood is a versatile solution suitable for a wide range of healthcare settings, including hospitals, compounding pharmacies, and healthcare facilities with in-house pharmaceutical compounding capabilities. By implementing the Sterile Hood, healthcare professionals can effectively mitigate the risk of contamination and ensure the quality and safety of compounded medications.Furthermore, Company XYZ provides comprehensive support and training for healthcare professionals in the proper use and maintenance of the Sterile Hood. This includes guidance on operational procedures, maintenance protocols, and ongoing technical support to maximize the performance and longevity of the equipment.The introduction of the Sterile Hood by Company XYZ underscores its commitment to advancing safety and quality in healthcare. With its innovative design and cutting-edge technology, the Sterile Hood is poised to become a leading solution in sterile compounding, empowering healthcare facilities to uphold the highest standards of sterility and safety in pharmaceutical compounding.As the demand for safe and reliable solutions in healthcare continues to grow, Company XYZ remains at the forefront of innovation, dedicated to providing advanced technologies and products that contribute to the improvement of healthcare practices and patient outcomes.In conclusion, the introduction of Company XYZ's Sterile Hood marks a significant advancement in the field of sterile compounding, offering healthcare facilities a reliable and efficient solution to enhance safety and sterility in pharmaceutical compounding. With its cutting-edge design and advanced features, the Sterile Hood is poised to make a substantial impact on the healthcare industry, ultimately contributing to improved quality and safety in healthcare settings.

Effective Clean Room Solutions for Your Business

Cleanrooms are an essential part of many industries, including pharmaceutical, biotechnology, electronics, and aerospace. These highly controlled environments are designed to minimize the contamination of particles, microbes, and other potentially harmful substances, ensuring the quality and safety of products and processes. In order to meet the strict cleanliness requirements of cleanroom environments, companies rely on specialized equipment and expertise to maintain the integrity of their facilities.One company that has been at the forefront of cleanroom technology is Portafab. With a history dating back to [year], Portafab has established itself as a leading provider of cleanroom solutions for a wide range of industries. The company's extensive experience and commitment to innovation have made it a trusted partner for businesses seeking reliable and efficient cleanroom solutions.Portafab's cleanroom systems are designed to meet the most stringent industry standards, providing an environment that is free from contaminants and conducive to the production of high-quality products. The company's cleanroom products are known for their durability, functionality, and flexibility, making them a popular choice for companies looking to maintain the highest levels of cleanliness in their facilities.Recently, Portafab announced the launch of its latest cleanroom technology, designed to further enhance the performance and efficiency of cleanroom environments. The new system incorporates advanced filtration and airflow control technologies, allowing for superior contamination control and a cleaner working environment. This innovative solution is expected to set a new standard for cleanroom performance, providing companies with a competitive edge in their respective industries.In addition to its cutting-edge technology, Portafab is also known for its exceptional customer service and support. The company's team of experts is dedicated to helping businesses find the right cleanroom solution for their specific needs, providing guidance and assistance every step of the way. From initial design and installation to ongoing maintenance and support, Portafab is committed to ensuring the success of its customers' cleanroom operations.Furthermore, Portafab understands the importance of sustainability in today's business environment, and its cleanroom solutions reflect this commitment. The company's cleanroom systems are designed to be energy-efficient and environmentally friendly, helping businesses reduce their carbon footprint and operate in a more sustainable manner. By incorporating the latest in sustainable technology and design, Portafab is helping its customers achieve their environmental goals while maintaining the highest standards of cleanliness and quality.With its reputation for excellence and a track record of delivering superior cleanroom solutions, Portafab continues to be a driving force in the industry. The company's dedication to innovation, quality, and customer satisfaction has earned it a strong position in the market and the trust of businesses worldwide. As the demand for cleanroom technology continues to grow, Portafab remains committed to pushing the boundaries of what is possible and providing cutting-edge solutions for the future.In conclusion, Portafab is a company that is synonymous with excellence in cleanroom technology. With its latest advancements and unwavering commitment to quality and customer satisfaction, Portafab is poised to continue leading the way in the cleanroom industry for years to come. Businesses in need of reliable and efficient cleanroom solutions can trust in Portafab's expertise and dedication to delivering the highest standards of cleanliness and performance.

Composite Panels: The Latest Innovation in Clean Room Technology

Clean Room Composite Panels: Revolutionizing the Construction IndustryIntroduction:Clean Room Composite Panels is a leading manufacturer and supplier in the construction industry, specializing in innovative building materials that enhance structural integrity and provide superior thermal insulation. Their commitment to research and development has allowed them to develop state-of-the-art composite panels that have revolutionized the cleanroom industry. With a wide range of applications, these panels have quickly gained popularity among architects, engineers, and construction professionals globally.Body:Clean Room Composite Panels are manufactured using advanced technology and premium quality raw materials. These panels consist of two metal sheets bonded to an insulating core material, such as polyurethane or mineral wool. This composition ensures high strength and durability while maintaining excellent thermal insulation properties.Applications:Clean Room Composite Panels have found widespread applications in various sectors, including pharmaceuticals, biotechnology, electronics, food processing, and healthcare. Their primary use is in cleanroom environments, where maintaining sterility, precise temperature control, and air quality are crucial. These panels create a controlled environment with minimal air contamination, making them ideal for laboratories, research facilities, and manufacturing units.Pharmaceutical Industry:Clean Room Composite Panels have become the preferred choice for pharmaceutical companies around the world. The panels' seamless construction and customizable design cater to the specific requirements of cleanrooms in pharmaceutical manufacturing. They provide a sterile environment necessary for drug development, ensuring quality control and compliance with regulatory standards.Electronics and Semiconductor Industry:In the electronics and semiconductor industry, precision and cleanliness are paramount. Clean Room Composite Panels offer excellent EMI/RFI shielding properties, safeguarding sensitive electronic equipment from interference. They also provide anti-static properties, preventing the build-up of static charge, which can damage electronic components. Moreover, these panels have a high fire resistance rating, ensuring safety in critical facilities.Food Processing and Healthcare Facilities:Clean Room Composite Panels are extensively used in the food processing industry to create controlled environments that meet strict regulatory requirements. They assist in maintaining hygienic conditions, preventing contamination, and facilitating easy cleaning and disinfection processes.Similarly, in healthcare facilities, such as hospitals and clinics, these panels are utilized for operating theaters, patient isolation rooms, and clean storage areas. The ability to maintain a sterile environment reduces the risk of infections and supports better patient outcomes.Energy Efficiency and Sustainability:Clean Room Composite Panels are designed to be energy efficient, helping occupants reduce their energy consumption and carbon footprint. The panels' insulating core material significantly reduces heat transfer, minimizing the load on HVAC systems. This results in lower energy costs and increased overall energy efficiency of the building.Additionally, Clean Room Composite Panels are manufactured with a focus on sustainability. The company employs eco-friendly manufacturing processes and uses recyclable materials in their panel manufacturing. This makes the panels an environmentally conscious choice for builders and developers looking to reduce their environmental impact.Conclusion:Clean Room Composite Panels have revolutionized the construction industry by providing superior structural strength, excellent thermal insulation, and a controlled environment for various applications. Their widespread use in cleanroom facilities and other sectors is a testament to their reliability, quality, and innovation. As the construction industry continues to prioritize energy efficiency and sustainability, Clean Room Composite Panels are poised to be at the forefront of building materials that meet the evolving needs of modern construction projects.

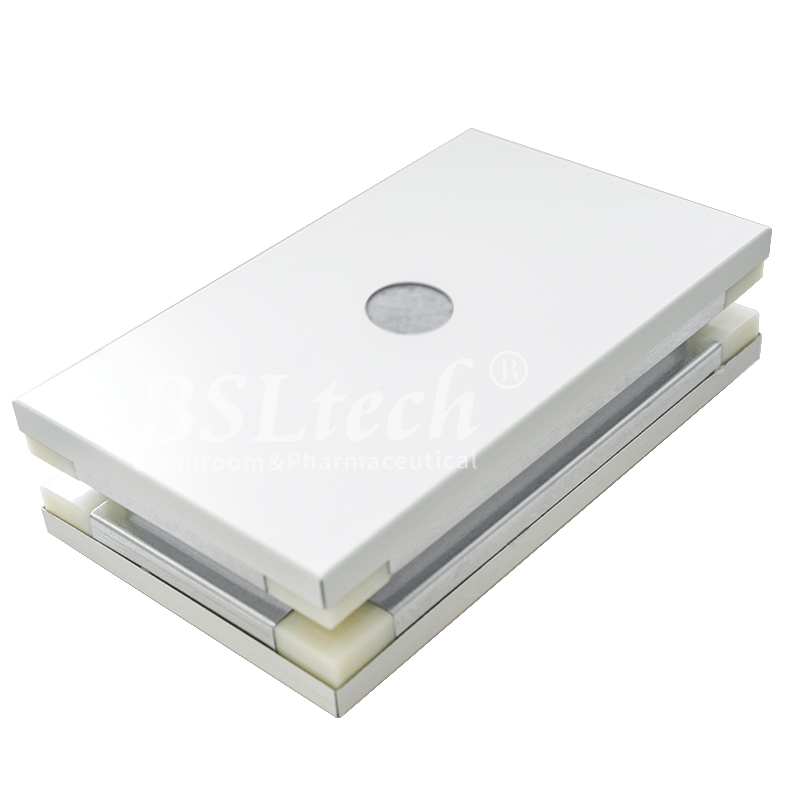

Innovative Pass Through Box: What You Need to Know

Pass Through Box: Ensuring Safe and Secure Transfer of Materials in Controlled EnvironmentsIn today's world, the need for working in controlled environments has become more important than ever. The pharmaceutical, biotech, and semiconductor industries, among others, require strict control over contamination and other environmental factors to ensure the safety and quality of their products. One crucial aspect of maintaining these controlled environments is the safe and secure transfer of materials and equipment, which is where the Pass Through Box comes into play.The Pass Through Box, also known as a pass-through chamber or transfer hatch, is a critical component in cleanroom and controlled environment technology. It is designed to allow the transfer of materials between two separate environments without compromising the integrity of either environment. This is achieved through the use of interlocking doors and other features that prevent the transfer of contaminants or other undesirable elements.{Company name}, a leading provider of cleanroom equipment and solutions, specializes in the design and manufacture of high-quality Pass Through Boxes for a wide range of industries. With a strong emphasis on innovation, quality, and reliability, {Company name} has established itself as a trusted partner for companies in need of controlled environment solutions.The Pass Through Box offered by {Company name} is designed to meet the specific needs and requirements of its customers. Whether it is for pharmaceutical manufacturing, biotech research, or semiconductor production, the company's Pass Through Boxes are built to ensure the safe and secure transfer of materials while maintaining the integrity of the controlled environments.One of the key features of {Company name}'s Pass Through Box is its user-friendly design. The company understands that ease of use and accessibility are important considerations in fast-paced and demanding environments. As a result, its Pass Through Boxes are equipped with intuitive controls and convenient features that make the transfer process efficient and hassle-free.Furthermore, {Company name}'s Pass Through Boxes are built with durability and reliability in mind. The company uses high-quality materials and advanced manufacturing techniques to create products that can withstand the rigors of daily use in demanding environments. This ensures that customers can rely on their Pass Through Boxes for years to come, without worrying about potential breakdowns or failures.In addition to its standard offerings, {Company name} also provides custom solutions for customers with unique or specialized requirements. The company's team of experts works closely with clients to understand their specific needs and develop tailored Pass Through Box solutions that meet those needs effectively. This personalized approach enables {Company name} to provide comprehensive solutions that are perfectly suited to the requirements of each customer.As part of its commitment to excellence, {Company name} also offers comprehensive support and services for its Pass Through Boxes. From installation and commissioning to maintenance and repairs, the company is dedicated to ensuring that its customers can rely on their equipment for optimal performance. This level of support further demonstrates {Company name}'s dedication to meeting the needs of its customers and maintaining the highest standards of quality and reliability.In conclusion, the Pass Through Box plays a crucial role in ensuring the safe and secure transfer of materials in controlled environments. With {Company name}'s commitment to innovation, quality, and reliability, customers can trust that they are receiving a superior product that meets their specific needs. By offering user-friendly designs, durable construction, and personalized solutions, {Company name} has established itself as a trusted partner for companies in need of controlled environment solutions.

Top tips for maintaining a cleanroom for effective operations

Panel Cleanroom Introduces Innovative Cleanroom Technology for Industrial and Research ApplicationsPanel Cleanroom, a leading provider of cleanroom solutions, has unveiled a new and innovative cleanroom technology designed to meet the growing demands of industrial and research applications. With over 20 years of experience in the cleanroom industry, Panel Cleanroom has continually demonstrated its commitment to delivering high-quality and reliable cleanroom solutions.The new cleanroom technology, developed by Panel Cleanroom's team of expert engineers and designers, offers a range of cutting-edge features that are set to revolutionize the way cleanrooms are utilized in various industries. The technology incorporates advanced air filtration systems, state-of-the-art monitoring and control systems, and adaptable modular designs to accommodate specific needs and requirements.The advancements in cleanroom technology are a result of Panel Cleanroom's dedication to staying at the forefront of innovation and adapting to the evolving needs of its customers. By consistently investing in research and development, Panel Cleanroom has been able to introduce solutions that provide greater efficiency, flexibility, and reliability for cleanroom environments.The new cleanroom technology is set to offer a wide range of benefits for industrial and research applications. With enhanced air filtration systems, the technology ensures a controlled and sterile environment, making it ideal for industries such as pharmaceuticals, biotechnology, electronics manufacturing, and aerospace. The state-of-the-art monitoring and control systems allow for real-time adjustments and maintenance of cleanroom conditions, ensuring optimal performance and safety.One of the key features of the new cleanroom technology is its adaptable modular designs, which allow for easy customization and expansion to meet specific requirements. This flexibility is particularly valuable for research applications, where cleanroom environments often need to be tailored to accommodate different experiments and processes.Panel Cleanroom's commitment to delivering high-quality and reliable cleanroom solutions has made it a trusted partner for a wide range of industries. The company's expertise in cleanroom technology has been instrumental in supporting the growth and success of its customers, helping them to achieve and maintain the highest standards of cleanliness and contamination control.In addition to its innovative cleanroom technology, Panel Cleanroom offers comprehensive support services, including installation, maintenance, and training. This ensures that customers can fully optimize the benefits of the new technology and continue to operate their cleanrooms at peak performance.The introduction of the new cleanroom technology solidifies Panel Cleanroom's position as a leader in the cleanroom industry. By continually pushing the boundaries of innovation and exceeding customer expectations, Panel Cleanroom is poised to remain at the forefront of cleanroom technology and deliver solutions that set new standards for cleanliness, efficiency, and reliability.As global demands for cleanroom solutions continue to rise, Panel Cleanroom is well-equipped to meet the needs of diverse industries and research applications. With its unwavering dedication to excellence and its commitment to innovation, Panel Cleanroom is set to continue shaping the future of cleanroom technology and setting new benchmarks for cleanroom performance and reliability.

Innovative Clean Room Door Designs for Maximum Efficiency

Clean Room Door Design: The New Innovation from [][Company Name], a leading provider of clean room solutions, has recently introduced a state-of-the-art clean room door design that promises to revolutionize the industry. The company, known for its commitment to quality and innovation, has once again raised the bar with this new product, which offers a perfect blend of functionality, aesthetics, and efficiency.The clean room door is an essential component in any controlled environment, as it serves as a barrier to prevent contaminants from entering the clean room. With this in mind, [] has meticulously designed a door that not only meets the highest standards of cleanliness and safety but also offers a range of innovative features that set it apart from traditional clean room doors.One of the key features of the new clean room door is its advanced sealing system, which ensures a tight and secure seal when the door is closed. This feature is crucial in maintaining the cleanliness of the environment inside the clean room, as even the smallest gap in the door can lead to contamination. The door's sealing system is designed to withstand high levels of air pressure differentials, further enhancing its effectiveness in preventing contaminants from entering the clean room.In addition to its superior sealing system, the clean room door also boasts a sleek and modern design that not only enhances the overall aesthetics of the clean room but also makes the door more user-friendly. The door is available in a variety of colors and finishes, allowing customers to choose a design that complements the overall look of their clean room. Furthermore, the door can be customized to meet specific size requirements, making it suitable for a wide range of clean room applications.Furthermore, the clean room door is equipped with advanced technological features, such as automated opening and closing mechanisms, which not only improve convenience for users but also minimize the risk of contamination by reducing the need for manual handling. This is particularly beneficial in environments where strict cleanliness and safety protocols must be adhered to at all times.Another standout feature of the new clean room door is its durability and longevity. Constructed from high-quality materials, the door is designed to withstand the rigors of a clean room environment, including frequent use and exposure to cleaning agents and disinfectants. This not only ensures a longer lifespan for the door but also reduces the need for frequent maintenance and replacement, resulting in cost savings for customers in the long run.[] is dedicated to providing comprehensive clean room solutions to its customers, and the introduction of the new clean room door is a testament to its ongoing commitment to innovation and excellence. The company's extensive experience in the clean room industry, combined with its team of skilled engineers and designers, has enabled it to develop a product that meets the evolving needs of clean room facilities across various industries.The new clean room door from [] is set to redefine standards for cleanliness, safety, and efficiency in controlled environments. With its cutting-edge design, advanced features, and unmatched durability, the door is poised to become the go-to choice for clean room facilities worldwide. As [] continues to innovate and push the boundaries of clean room technology, customers can expect even more groundbreaking solutions in the future.