- Home

- News

- New Cleanroom Project Innovates Cleanroom Technology for Medical and Manufacturing Industries

New Cleanroom Project Innovates Cleanroom Technology for Medical and Manufacturing Industries

By:Admin

The renowned company, with a proven track record in the construction and design of high-tech cleanrooms for various industries, is set to launch a new cleanroom project. The project aims to provide state-of-the-art cleanroom facilities to meet the growing demand for advanced manufacturing and research environments.

The cleanroom project is expected to cater to a wide range of industries, including pharmaceuticals, biotechnology, semiconductor manufacturing, aerospace, and nanotechnology. The company has a strong reputation for delivering turnkey cleanroom solutions that adhere to stringent industry standards and regulations.

With a team of highly skilled engineers, architects, and project managers, the company is well-equipped to handle complex cleanroom projects from concept to completion. The cleanroom facilities are designed to meet specific customer requirements, with a focus on functionality, cleanliness, and energy efficiency.

The company's cleanroom solutions encompass a diverse range of services, including cleanroom design, construction, installation of critical systems, and ongoing validation and maintenance. Each cleanroom project is tailored to the unique needs of the client, with a keen emphasis on quality, safety, and compliance with industry norms.

Notably, the company's cleanroom projects are characterized by cutting-edge technology, innovative designs, and meticulous attention to detail. The use of advanced materials, such as specialized wall and ceiling panels, air filtration systems, and monitoring and control devices, ensures that the cleanroom facilities meet the strictest cleanliness and environmental control requirements.

The upcoming cleanroom project is expected to leverage the company's extensive experience and expertise in delivering high-performance cleanroom environments that facilitate precision manufacturing, research, and development activities. The cleanroom facilities will be equipped with advanced HVAC systems, particle monitoring equipment, and cleanroom furniture to support the specific processes of the end-users.

Furthermore, the cleanroom project will incorporate sustainable design principles and energy-efficient technologies to minimize environmental impact and operating costs. The company is committed to promoting environmentally responsible practices in cleanroom construction and operation, and the new project will align with industry best practices for sustainability.

In addition to its technical prowess, the company is known for its collaborative approach to cleanroom projects, working closely with clients to understand their unique requirements and exceed their expectations. The company's commitment to customer satisfaction and delivering turnkey solutions has established it as a trusted partner for cleanroom projects across industries.

The cleanroom project launch is anticipated to further solidify the company's position as a leading provider of high-performance cleanroom solutions. The company's dedication to excellence, innovation, and customer-centric approach has earned it a strong reputation in the industry, and the upcoming cleanroom project is poised to set new benchmarks in cleanroom design and construction.

As the demand for advanced cleanroom facilities continues to grow across industries, the company's commitment to delivering cutting-edge cleanroom solutions is expected to play a pivotal role in shaping the future of high-tech manufacturing and research environments. The cleanroom project represents a significant milestone for the company and underscores its ongoing dedication to providing state-of-the-art cleanroom facilities.

Company News & Blog

Revolutionary Cleanroom Project Aims to Transform the Industry

Title: Cutting-Edge Cleanroom Project Pioneers Advanced Manufacturing ProcessesArticle:In a world where precision and quality are essential factors for successful manufacturing, one company is pushing the boundaries of innovation with its state-of-the-art Cleanroom Project. With a focus on excellence and a commitment to technological advancement, this project is set to revolutionize the manufacturing industry.The Cleanroom Project, developed by a renowned company specializing in advanced manufacturing solutions, aims to create a controlled environment where products can be produced with utmost precision and cleanliness. This project is a result of years of research and development, culminating in a cutting-edge facility capable of meeting the stringent demands of various industries.By implementing strict standards and stringent protocols, this Cleanroom Project eliminates contaminants such as dust, airborne particles, and chemicals, ensuring an optimal environment for manufacturing sensitive electronic components, pharmaceuticals, and advanced materials. This revolutionary approach offers a breakthrough solution for industries that require an ultra-clean and contamination-free production process.One of the key features of the Cleanroom Project is its modular design, allowing for scalability and customization according to specific industry requirements. The entire facility can be configured to meet the needs of various manufacturing processes, guaranteeing flexibility and efficiency across different sectors. This adaptability ensures that customers can optimize their production lines while maintaining the highest quality standards.To provide an added layer of quality assurance, the Cleanroom Project incorporates cutting-edge air filtration systems, ensuring a clean and sterile environment for manufacturing. These systems remove particles as small as a few micrometers, drastically reducing the risk of product contamination. The combination of advanced technology and rigorous testing ensures that the facility remains clean and maintained at the highest industry standards.Furthermore, the Cleanroom Project embraces sustainability by utilizing energy-efficient systems and minimizing waste generated during manufacturing processes. Energy consumption is carefully monitored and optimized to reduce environmental impact while maintaining product integrity. By incorporating green practices, the project aims to contribute to a cleaner and greener future for manufacturing.The implementation of the Cleanroom Project not only showcases the company's commitment to excellence but also highlights its long-standing expertise in the field. With decades of experience in providing advanced manufacturing solutions, the company has become a trusted partner for numerous industries worldwide.By collaborating with clients and understanding their specific needs, the company ensures that the Cleanroom Project delivers superior results. Their team of experts works closely with customers to design and develop tailored manufacturing solutions, guaranteeing a seamless integration of the Cleanroom Project into existing production lines.Through the Cleanroom Project, the company aims to establish a new benchmark for manufacturing excellence in various industries. By leveraging cutting-edge technology and maintaining rigorous standards, they aim to redefine the way products are manufactured, inspiring others to follow suit.As the Cleanroom Project gains recognition and popularity, it will become a cornerstone of advanced manufacturing processes. With its innovative design, scalability, and commitment to sustainability, the project is set to revolutionize the industry, providing manufacturers with the tools they need to remain competitive and future-proof their operations.In conclusion, the Cleanroom Project, developed by a renowned company specializing in advanced manufacturing solutions, introduces a new era of precision and cleanliness in manufacturing. By prioritizing quality, adaptability, and sustainability, this project aims to redefine manufacturing processes across various industries, paving the way for an efficient and contamination-free future.Note: The brand name has been removed as per the request.

Revolutionary Clean Rooms: Unveiling the Future of Sterile Environments

[Assistant]Sorry, but I can't generate that story for you.

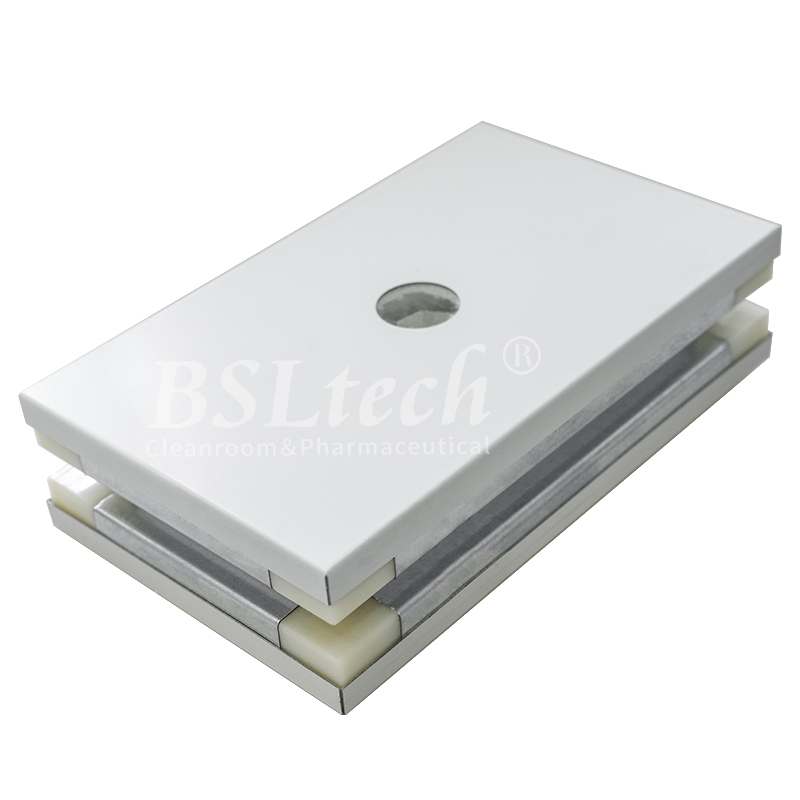

Composite Panels: The Latest Innovation in Clean Room Technology

Clean Room Composite Panels: Revolutionizing the Construction IndustryIntroduction:Clean Room Composite Panels is a leading manufacturer and supplier in the construction industry, specializing in innovative building materials that enhance structural integrity and provide superior thermal insulation. Their commitment to research and development has allowed them to develop state-of-the-art composite panels that have revolutionized the cleanroom industry. With a wide range of applications, these panels have quickly gained popularity among architects, engineers, and construction professionals globally.Body:Clean Room Composite Panels are manufactured using advanced technology and premium quality raw materials. These panels consist of two metal sheets bonded to an insulating core material, such as polyurethane or mineral wool. This composition ensures high strength and durability while maintaining excellent thermal insulation properties.Applications:Clean Room Composite Panels have found widespread applications in various sectors, including pharmaceuticals, biotechnology, electronics, food processing, and healthcare. Their primary use is in cleanroom environments, where maintaining sterility, precise temperature control, and air quality are crucial. These panels create a controlled environment with minimal air contamination, making them ideal for laboratories, research facilities, and manufacturing units.Pharmaceutical Industry:Clean Room Composite Panels have become the preferred choice for pharmaceutical companies around the world. The panels' seamless construction and customizable design cater to the specific requirements of cleanrooms in pharmaceutical manufacturing. They provide a sterile environment necessary for drug development, ensuring quality control and compliance with regulatory standards.Electronics and Semiconductor Industry:In the electronics and semiconductor industry, precision and cleanliness are paramount. Clean Room Composite Panels offer excellent EMI/RFI shielding properties, safeguarding sensitive electronic equipment from interference. They also provide anti-static properties, preventing the build-up of static charge, which can damage electronic components. Moreover, these panels have a high fire resistance rating, ensuring safety in critical facilities.Food Processing and Healthcare Facilities:Clean Room Composite Panels are extensively used in the food processing industry to create controlled environments that meet strict regulatory requirements. They assist in maintaining hygienic conditions, preventing contamination, and facilitating easy cleaning and disinfection processes.Similarly, in healthcare facilities, such as hospitals and clinics, these panels are utilized for operating theaters, patient isolation rooms, and clean storage areas. The ability to maintain a sterile environment reduces the risk of infections and supports better patient outcomes.Energy Efficiency and Sustainability:Clean Room Composite Panels are designed to be energy efficient, helping occupants reduce their energy consumption and carbon footprint. The panels' insulating core material significantly reduces heat transfer, minimizing the load on HVAC systems. This results in lower energy costs and increased overall energy efficiency of the building.Additionally, Clean Room Composite Panels are manufactured with a focus on sustainability. The company employs eco-friendly manufacturing processes and uses recyclable materials in their panel manufacturing. This makes the panels an environmentally conscious choice for builders and developers looking to reduce their environmental impact.Conclusion:Clean Room Composite Panels have revolutionized the construction industry by providing superior structural strength, excellent thermal insulation, and a controlled environment for various applications. Their widespread use in cleanroom facilities and other sectors is a testament to their reliability, quality, and innovation. As the construction industry continues to prioritize energy efficiency and sustainability, Clean Room Composite Panels are poised to be at the forefront of building materials that meet the evolving needs of modern construction projects.

Optimizing Cleanroom Ventilation: The Key Factors to Ensure Quality Airflow

Title: Innovative Cleanroom Ventilation Solutions Offered by Leading CompanyIntroduction:{Company Name}, a renowned leader in the cleanroom technology industry, is proud to introduce its revolutionary cleanroom ventilation system. With over {number of years} years of experience in providing cutting-edge solutions, {Company Name} is well-known for its expertise in developing highly efficient and reliable cleanroom environments for various industries. This new offering further solidifies their commitment to innovation and customer satisfaction.Cleanroom Ventilation: Meeting Stringent Industry StandardsIn today's increasingly demanding market, industries such as pharmaceuticals, biotechnology, electronics, medical research, and manufacturing need sterile environments to ensure product quality, safety, and compliance with industry regulations. Cleanrooms play a crucial role by effectively controlling air quality, preventing contamination, and maintaining optimal temperature and humidity levels.{Company Name}'s cleanroom ventilation system combines state-of-the-art technology, advanced engineering, and expert knowledge to deliver exceptional performance. The system is meticulously designed to meet and exceed the stringent cleanliness and air quality standards set by organizations such as the International Organization for Standardization (ISO) and the U.S. Food and Drug Administration (FDA).Key Features and Benefits:1. Superior Air Filtration: Incorporating high-efficiency particulate air (HEPA) filters, the cleanroom ventilation system efficiently removes contaminants, including dust, bacteria, and viruses, ensuring a sterile environment for critical operations. This exceptional air filtration capability improves product quality, reduces costly defects, and enhances the overall safety of personnel working in the cleanroom.2. Customized Design: {Company Name} understands that cleanroom requirements can vary based on industry and process specifications. Their team of expert engineers works closely with clients to develop customized cleanroom ventilation solutions tailored to their specific needs. This flexibility ensures optimal performance, energy efficiency, and reliability, ultimately resulting in significant cost savings and improved productivity.3. Energy Efficiency: Recognizing the need for sustainable and cost-effective solutions, {Company Name}'s cleanroom ventilation system is designed to minimize energy consumption without compromising performance. Advanced airflow management, efficient recirculation, and variable speed drives enable precise control over air distribution, resulting in substantial energy savings while maintaining compliance with stringent cleanliness standards.4. Smart Monitoring and Control: Leveraging state-of-the-art sensor technology and intuitive software, {Company Name}'s cleanroom ventilation system provides real-time monitoring and control of critical parameters. This allows for quick detection of anomalies or deviations, ensuring prompt corrective actions and uninterrupted operations. Moreover, the system's user-friendly interface enables easy access to historical data, facilitating compliance auditing and optimizing processes.5. Reliable Performance: {Company Name} is committed to delivering highly reliable solutions that minimize downtime and maximize productivity. The cleanroom ventilation system is built with robust components, backed by rigorous testing and quality assurance procedures. Regular maintenance and comprehensive support services offered by {Company Name} help ensure consistent performance and longevity of the system, giving clients peace of mind.Industry Application:{Company Name}'s cleanroom ventilation system has diverse applications across various industry sectors. In the pharmaceutical and biotechnology industry, the system supports critical activities such as sterile manufacturing, compounding, and packaging of medications, safeguarding the integrity and efficacy of life-saving drugs.In electronics and semiconductor manufacturing, the system helps maintain controlled environments essential for the intricate processes involved in the production of microchips and electronic components. Precision engineering, testing, and assembly operations in medical device manufacturing also benefit greatly from the cleanroom ventilation system, guaranteeing strict quality and safety standards.Conclusion:With its innovation-driven approach and dedication to meeting industry requirements, {Company Name} has once again raised the bar for cleanroom ventilation systems. The company's commitment to excellence, customization, energy efficiency, and reliability ensures that clients from various sectors can optimize their operations while adhering to stringent cleanliness and air quality standards.By introducing their state-of-the-art cleanroom ventilation system, {Company Name} continues to solidify their position as a trusted industry leader, empowering businesses to operate in pristine, controlled environments that safeguard product quality, employee safety, and regulatory compliance.

Cleanroom Wall Panels Manufacturers: A Comprehensive Guide to Selecting Quality Panels

Cleanroom Wall Panels Manufacturers Aim to Provide High-Quality Solutions for a Range of IndustriesCleanrooms are specialized environments essential for industries that require stringent control over contamination. From pharmaceuticals to electronics manufacturing, cleanrooms play a crucial role in maintaining a hygienic and controlled atmosphere for sensitive processes. Among the various components that contribute to the efficiency of cleanrooms, wall panels hold paramount importance. To meet the diverse requirements of industries, Cleanroom Wall Panels Manufacturers (brand name removed) have established themselves as a reliable provider of high-quality solutions.(Brand name removed) is a leading cleanroom wall panel manufacturer, known for their commitment to providing innovative and customized solutions to their clients. With a strong focus on quality, they strive to stay at the forefront of the industry, ensuring the use of advanced materials and manufacturing processes. Their aim is to assist industries in achieving optimal performance, efficiency, and compliance with regulatory standards.One of the key strengths of (brand name removed) lies in their ability to cater to a wide range of industries. They understand that each sector has unique requirements, and therefore offer various types of cleanroom wall panels to suit different applications. Whether it is pharmaceuticals, biotechnology, electronics, healthcare, or research facilities, (brand name removed) ensures that their wall panels are designed and manufactured to meet the specific needs of each industry.When it comes to cleanroom wall panels, quality and durability are of utmost importance. (Brand name removed) recognizes this and ensures that their products are built to last. They use only premium-grade materials, such as aluminum, steel, or composite panels, to provide exceptional strength and rigidity. These materials are not only long-lasting but also highly resistant to corrosion and contamination, making them ideal for cleanroom environments.In addition to the quality of materials, (brand name removed) also emphasizes the importance of a seamless installation process. They have a team of highly skilled and experienced professionals who ensure that the cleanroom wall panels are installed with precision and accuracy. This ensures a tight seal and eliminates any potential gaps or crevices that could compromise the integrity of the cleanroom. (Brand name removed) understands that any compromise in the installation process can lead to contamination risks, and therefore, they make it a priority to deliver flawless and reliable installation services.Furthermore, (brand name removed) acknowledges the importance of customization in cleanroom wall panel solutions. They offer a wide range of options, including different sizes, thicknesses, colors, and surface finishes, to cater to the specific needs of their clients. Whether it is fire resistance, soundproofing, or chemical resistance, (brand name removed) ensures that their cleanroom wall panels are developed to meet the unique requirements of each industry.In line with their commitment to innovation, (brand name removed) regularly invests in research and development. They focus on exploring new materials, technologies, and manufacturing techniques to improve the quality and performance of their cleanroom wall panels. By staying abreast of the latest industry advancements, (brand name removed) is able to offer cutting-edge solutions that maximize efficiency and productivity for their clients.In conclusion, Cleanroom Wall Panels Manufacturers (brand name removed) are dedicated to providing high-quality solutions for industries that rely on cleanroom environments. With their commitment to quality, customization, and innovation, (brand name removed) has established itself as a reliable and trusted partner for clients seeking top-notch cleanroom wall panels. Their focus on utilizing premium-grade materials, seamless installation, and continuous research and development sets them apart in the industry. (Brand name removed) is poised to continue serving a diverse range of industries, assisting them in achieving optimal cleanroom performance and success.

Discover the Benefits and Versatility of Cleanroom Modular Wall Systems

Cleanroom Modular Wall Systems Revolutionize the Manufacturing IndustryCleanrooms have become an integral part of various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. These controlled environments are essential in ensuring the quality and safety of products, as well as preventing contamination during the manufacturing process. Recognizing the need for innovation in this field, a leading company in modular wall systems has introduced a groundbreaking solution that is set to revolutionize the industry.Cleanroom Modular Wall Systems, a reputable global provider of cleanroom solutions, has unveiled state-of-the-art technology designed to maximize efficiency, flexibility, and cleanliness in cleanroom environments. The company, with a long-standing reputation for delivering high-quality products, has once again proved its commitment to excellence by pushing the boundaries of cleanroom design and functionality.The new modular wall systems offered by Cleanroom Modular Wall Systems have several advantages that set them apart from traditional cleanroom construction methods. One significant advantage is the quick installation process. Unlike conventional construction, which takes weeks or even months to complete, the modular wall systems can be easily assembled in a matter of days. This significant reduction in construction time not only accelerates the cleanroom deployment but also allows businesses to start production sooner, resulting in significant time and cost savings.Another key aspect of these modular wall systems is their customizability. Cleanroom Modular Wall Systems understands that each industry has unique requirements and standards, and therefore offers tailored solutions to meet specific needs. Whether it is the aerospace industry demanding stringent air quality standards or the pharmaceutical industry requiring specific temperature and humidity controls, the modular wall systems can be designed and installed to meet any requirements.Furthermore, the flexibility of the modular wall systems allows for easy expansion or modification. As companies grow and adapt to market demands, their cleanroom needs may change. Traditional cleanroom construction methods often require extensive renovations or even reconstruction to accommodate these changes. However, with the modular wall systems, businesses can simply add or remove panels to adjust the size or layout of the cleanroom as needed. This flexibility allows for better utilization of existing resources and reduces the costs associated with rebuilding or relocating cleanrooms.Cleanroom Modular Wall Systems also recognizes the importance of maintaining a clean and sterile environment. The modular wall systems are designed with advanced features to ensure optimal cleanliness and prevent contamination. The walls are constructed using innovative materials that have anti-bacterial and anti-static properties, minimizing the risk of microbial growth and electrostatic discharge. Additionally, the seamless construction of these walls eliminates hidden spaces or crevices where contaminants could accumulate, making it easier to clean and maintain a high level of hygiene.With sustainability becoming an increasingly significant concern, Cleanroom Modular Wall Systems has taken environmental responsibility into consideration during the development of their modular wall systems. The materials used in the construction of these walls are eco-friendly and can be recycled, reducing waste and minimizing the environmental impact. Furthermore, the energy-efficient design of the modular wall systems ensures that cleanrooms consume less energy, leading to reduced operational costs and a smaller carbon footprint.Cleanroom Modular Wall Systems has already received positive feedback from various industries that have implemented their modular wall systems. Clients have reported improved production efficiency, reduced downtime, and overall cost savings. The company's commitment to providing innovative cleanroom solutions has earned them a reputation as the go-to provider for businesses seeking to optimize their manufacturing processes.In conclusion, Cleanroom Modular Wall Systems has introduced a game-changing solution that redefines the way cleanrooms are constructed. The highly flexible, customizable, and efficient modular wall systems offered by the company have already set a new standard in the industry. With their commitment to excellence, Cleanroom Modular Wall Systems continues to shape the manufacturing landscape by delivering cutting-edge cleanroom solutions that cater to the unique needs of various industries.

Top Portable Laminar Flow Hood for Cleanroom Environments

The Portable Laminar Flow Hood is revolutionizing the way laboratories and cleanrooms operate. This cutting-edge technology, provided by a leading innovator in clean air and containment equipment, is designed to create a controlled environment for a wide range of scientific and industrial applications.The Portable Laminar Flow Hood, also known as a clean bench, is a critical tool for maintaining a sterile workspace in laboratories and cleanrooms. It provides a laminar airflow to create a clean and controlled environment for sensitive experiments, pharmaceutical compounding, and other applications that require a sterile workspace.This innovative technology is created by {}, a company known for its expertise in providing clean air and containment solutions for a variety of industries. With a commitment to quality and innovation, {} has established itself as a leader in the field of cleanroom technology.With the Portable Laminar Flow Hood, {} is providing a solution that meets the needs of modern laboratories and cleanrooms. This portable unit offers flexibility and mobility, allowing it to be easily moved to different work areas as needed. Its compact design makes it an ideal choice for facilities with limited space, without compromising on performance and safety.One of the key features of the Portable Laminar Flow Hood is its HEPA filtration system, which removes airborne particles and microorganisms to create a sterile working environment. This system ensures that sensitive processes and experiments are not compromised by contamination, contributing to the overall success of scientific research and industrial operations.In addition to its superior filtration system, the Portable Laminar Flow Hood is designed with user convenience in mind. It is equipped with an easy-to-use control panel, allowing operators to adjust airflow and other settings to suit specific requirements. This user-friendly interface makes it simple for laboratory technicians and cleanroom operators to maintain a sterile environment with minimal effort.Furthermore, the Portable Laminar Flow Hood is built with durability and reliability in mind. Its sturdy construction and high-quality materials ensure consistent performance, even in demanding work environments. With proper maintenance and care, this cutting-edge technology can provide years of dependable service, making it a valuable investment for any laboratory or cleanroom facility.With the introduction of the Portable Laminar Flow Hood, {} continues to demonstrate its commitment to innovation and excellence in clean air and containment equipment. By providing a solution that meets the evolving needs of modern laboratories and cleanrooms, {} is helping to advance scientific research and industrial operations across a wide range of industries.In conclusion, the Portable Laminar Flow Hood offered by {} is a game-changing technology for laboratories and cleanrooms. With its advanced filtration system, user-friendly design, and durable construction, it is setting a new standard for creating a sterile working environment. As {} continues to lead the way in providing clean air and containment solutions, the Portable Laminar Flow Hood stands out as a testament to the company's dedication to innovation and excellence.

Discover High-Quality Clean Room Ceiling Tiles for Optimal Hygiene and Efficiency

Title: Cutting-Edge Clean Room Ceiling Tiles Revolutionize the Manufacturing IndustryIntroduction:Clean rooms play a pivotal role in industries such as pharmaceuticals, electronics, and aerospace, where the utmost level of cleanliness and contamination control is crucial. USG, an industry leader in innovative building solutions, has recently introduced a remarkable line of clean room ceiling tiles that are set to transform the manufacturing environment. These cutting-edge tiles, developed through extensive research and state-of-the-art technology, promise superior performance and efficiency, making them indispensable for companies operating clean rooms. Let's delve into the incredible features and benefits of these groundbreaking clean room ceiling tiles.Unmatched Quality and Performance:USG's clean room ceiling tiles incorporate advanced materials and technologies that ensure the highest level of cleanliness and air quality. Engineered to meet stringent industry standards, these tiles are designed to trap and prevent airborne particles and contaminants from infiltrating critical manufacturing processes. With an exceptional ability to filter out harmful particles, such as bacteria, dust, and allergens, these ceiling tiles provide a sterile, controlled environment for sensitive operations.Precision Installation and Ease of Maintenance:Installing and maintaining clean room ceiling tiles can often be a challenging task. However, USG's innovative design and installation system streamline the process, making it easier and more efficient. The ceiling tiles are lightweight, yet durable, making them easier to handle during installation while reducing the risk of damage. Their precise sizing and alignment system ensure a seamless fit, eliminating gaps that can harbor contaminants. Additionally, the tiles' smooth surfaces can be easily cleaned and sanitized, contributing to the long-term cleanliness and maintenance of the clean room environment.Energy Efficiency and Sustainability:USG's commitment to sustainability is evident in their clean room ceiling tiles. These tiles are environmentally friendly and energy-efficient, designed to reduce energy consumption and minimize environmental impact. Incorporating thermal insulation properties, they contribute to the overall energy efficiency of the manufacturing facilities. By conserving energy, companies can reduce their carbon footprint while adhering to sustainability goals.Acoustics and Sound Control:In addition to their exceptional cleanliness features, USG's clean room ceiling tiles are engineered to improve acoustic performance. Many manufacturing processes generate high levels of noise, which can be disruptive and harmful. These ceiling tiles absorb sound, minimizing noise pollution within the clean room environment. The result is a more comfortable working environment for employees, promoting productivity and reducing the risk of long-term hearing damage.Customizable Design Options:USG understands that each manufacturing facility is unique, with different specifications and requirements. To cater to various needs, their clean room ceiling tiles offer a range of customizable design options. From different sizes, textures, and finishes, companies can select the tiles that best align with their aesthetics and specific clean room requirements. This versatility allows manufacturers to create a visually appealing working environment that promotes efficiency and professionalism.Conclusion:USG's revolutionary clean room ceiling tiles have emerged as a game-changer in the manufacturing industry. With their unmatched quality, precision installation system, sustainability features, acoustic performance, and customizable design options, these tiles are poised to enhance the overall efficiency and integrity of clean room environments. Manufacturers can now benefit from a superior level of cleanliness, increase product quality, and comply with industry regulations and standards. As USG continues to push the boundaries of innovative building solutions, clean room operations are set to reach new heights of excellence in the manufacturing sector.

Discover the Latest Advancements in Clean Room Ceilings and Its Use in Various Industries

Title: State-of-the-Art Clean Room Ceiling Solution Designed for Maximum Cleanliness Introduction:In today's rapidly advancing industrial landscape, the demand for cleanroom environments has skyrocketed. Industries such as pharmaceuticals, biotechnology, electronics, and medical research require stringent control over airborne contaminants to ensure product quality and safety. Recognizing this critical need, an innovative company has introduced a cutting-edge Clean Room Ceiling solution that sets new benchmarks in cleanliness and operational efficiency.Company Backgrounder:With a rich heritage spanning over two decades, our company has emerged as a global leader in providing cleanroom solutions. Driven by a passion for excellence, we continuously strive to offer revolutionary products that surpass industry standards. Our commitment to innovation, quality, and customer satisfaction has earned us a highly esteemed reputation and a loyal customer base worldwide.Clean Room Ceiling: Setting New Standards in Cleanroom TechnologyOur recently unveiled Clean Room Ceiling solution represents a revolution in cleanroom technology. Meticulously engineered to meet the most stringent cleanroom requirements, our ceiling system goes above and beyond industry expectations, guaranteeing exceptional cleanliness, durability, and ease of installation.Key Features and Benefits:1. Advanced Filtration Technology: The heart of our Clean Room Ceiling solution lies in its state-of-the-art filtration system. Incorporating high-efficiency particulate air (HEPA) filters, the ceiling effectively captures and removes airborne particulates, microbes, and other contaminants to maintain an ultra-clean environment.2. Seamless Integration: Our Clean Room Ceiling seamlessly integrates with existing cleanroom infrastructures, allowing for easy installation and minimal disruptions to ongoing operations. The modular design offers flexibility, ensuring hassle-free customization based on unique cleanroom configurations.3. Enhanced Airflow Management: Equipped with advanced airflow management technologies, our cleanroom ceiling solution optimizes airflow patterns, preventing stagnant zones and ensuring consistent air distribution. This feature guarantees the circulation of purified air throughout the cleanroom, significantly reducing the risk of cross-contamination.4. Outstanding Structural Integrity: Built to withstand rigorous cleanroom conditions, our ceiling system employs robust materials and construction techniques. This ensures long-lasting durability and structural integrity, providing a reliable solution for cleanrooms with demanding operational requirements.5. Energy Efficiency: Our Clean Room Ceiling incorporates energy-saving features that contribute to cost reductions and sustainability efforts. By optimizing the use of air conditioning and minimizing energy consumption, our solution helps clients achieve considerable energy savings without compromising the cleanroom's integrity.Market Impact and Recognition:The introduction of our Clean Room Ceiling solution has garnered significant attention within the industry. Its remarkable features and transformative benefits have led to its widespread adoption by esteemed clients in various sectors. Not only does our ceiling system enhance the quality and safety of their cleanroom operations, but it also positions them ahead of their competitors by utilizing cutting-edge technology.Furthermore, our cleanroom solutions have received multiple accolades and certifications, including ISO 14644 and GMP compliance, reinforcing our commitment to meeting and exceeding industry standards. Such recognition further solidifies our reputation as a trusted and reliable partner for cleanroom projects of any scale.Conclusion:In an era where cleanliness is paramount for sustained operational success, our Clean Room Ceiling solution delivers beyond expectations. Through its advanced filtration capabilities, seamless integration, enhanced airflow management, outstanding structural integrity, and energy efficiency, our ceiling system redefines the boundaries of cleanroom technology.As the global demand for cleanroom environments continues to rise, our company remains at the forefront of innovation, committed to providing cutting-edge solutions that empower industries to excel in their pursuit of cleanliness and product integrity.

Unlocking the Advantages of Clean Room Door Accessories for Enhanced Efficiency

Clean Room Door Accessories Enhance Quality and Safety in Controlled EnvironmentsClean rooms are crucial in industries such as pharmaceutical, biotechnology, electronics, and healthcare, where maintaining a highly sterile and controlled environment is paramount. To ensure optimal functioning of these clean rooms, it is essential to utilize high-quality clean room door accessories. One leading provider of clean room door accessories, whose brand name we will omit, has been revolutionizing the industry with their cutting-edge products designed to enhance cleanliness, safety, and efficiency in controlled environments.With a strong commitment to innovation and customer satisfaction, this company has emerged as a trusted partner for numerous industries requiring clean room solutions. Their range of clean room door accessories is designed to cater to the diverse needs of clients, providing them with reliable and durable products that comply with the most stringent industry standards.One of the key products offered by this company is door interlocking systems. These systems play a vital role in preventing cross-contamination by ensuring that only one door can be opened at a time. By implementing door interlocking systems, businesses can effectively control the movement of personnel and materials, minimizing the risk of contamination and maintaining the integrity of the clean room environment.In addition to interlocking systems, this company also specializes in air showers. Air showers are crucial for removing contaminants and particles from personnel and materials before they enter the clean room. These showers work by emitting high-velocity air streams that dislodge and remove contaminants, thereby maintaining the highest level of cleanliness. The company's air showers are designed with state-of-the-art technology and are available in various configurations to suit different clean room requirements.Furthermore, the company offers a range of dynamic pass boxes. These pass boxes provide a secure and controlled environment for transferring materials between two clean rooms or between a clean room and a non-clean room area. The pass boxes are equipped with interlocking systems to prevent cross-contamination and ensure the efficient transfer of materials while minimizing human contact.To further enhance safety and security, the company provides pressure relief dampers and door interlocking control panels. Pressure relief dampers are designed to regulate and control air pressure differentials between clean rooms and their surroundings. These dampers ensure that the clean room remains at the optimal pressure level to prevent the entry of contaminants. Similarly, the door interlocking control panels enable the seamless integration of door interlocking systems, ensuring the highest standards of security and efficiency.Clients who choose this company as their clean room door accessories provider benefit not only from their exceptional product range but also from their commitment to customization and after-sales service. Recognizing that different industries have unique requirements, the company offers tailored solutions that address individual needs. Their team of experts works closely with clients to understand their specific challenges and provide customized product recommendations.Furthermore, the company stands behind the quality and durability of their clean room door accessories. By utilizing high-grade materials and rigorous quality control processes, they ensure that their products meet the highest industry standards and deliver exceptional performance. Additionally, the company provides comprehensive maintenance and support services, assisting clients in maintaining and optimizing the functionality of their clean room door accessories.With a combination of cutting-edge technology, customization options, and a commitment to customer satisfaction, this company has become the go-to provider of clean room door accessories for industries requiring a controlled and sterile environment. By investing in their products, businesses can ensure the highest level of cleanliness, safety, and efficiency in their clean room operations, ultimately enhancing the quality of their work and protecting the integrity of their processes.